New SNAP-X provides advanced deburring

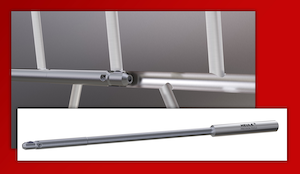

Heule Precision Tools introduces the SNAP-X line for cross hole deburring of main bores with multiple cross bores.

This unique technology, built on the proven Heule SNAP platform, provides a reliable, automated solution that reduces cycle time, improves consistency, and eliminates secondary operations. SNAP-X deburrs intersecting cross directly through the main bore in one pass. Different diameters and angles can be reliably processed within permissible tolerance range and verified feasibility. With two cutting edges that work in both directions, it provides forward and backward cutting. A special guiding edge and gliding section prevent damage to the main bore during operation. Blades can be swapped by hand quickly and without tools, keeping downtime to a minimum. Each SNAP-X is custom-engineered and built for each customer’s specific application. SNAP-X is ideally suited for high volume production runs requiring deburring main bores with multiple intersecting cross bores if different diameters and angles (up to nearly a 1:1 ratio), on applications like drive shafts, transmission components, and other precision machined parts requiring consistent deburring quality.

This unique technology, built on the proven Heule SNAP platform, provides a reliable, automated solution that reduces cycle time, improves consistency, and eliminates secondary operations. SNAP-X deburrs intersecting cross directly through the main bore in one pass. Different diameters and angles can be reliably processed within permissible tolerance range and verified feasibility. With two cutting edges that work in both directions, it provides forward and backward cutting. A special guiding edge and gliding section prevent damage to the main bore during operation. Blades can be swapped by hand quickly and without tools, keeping downtime to a minimum. Each SNAP-X is custom-engineered and built for each customer’s specific application. SNAP-X is ideally suited for high volume production runs requiring deburring main bores with multiple intersecting cross bores if different diameters and angles (up to nearly a 1:1 ratio), on applications like drive shafts, transmission components, and other precision machined parts requiring consistent deburring quality.

How it Works

This unique technology features a simple design with few components. The radially supported and spring-loaded blade penetrates the cross bore in work feed and deburrs it, regardless of the diameter of the cross bore. The blade can be changed by hand with no tools. With two cutting edges, the SNAP-X cuts when rotating in either direction. The guiding edge of the SNAP-X blade moves it back into the tool body when exiting the cross bore, protecting the main bore.

The tool blade is positioned in rapid feed in front of the cross bore to be deburred. In work feed forward and with work speed, the edges of the intersection are machined. With clockwise rotation all intersecting bores are deburred in a single pass. The spindle rotation is reversed, machining the cross bores a second time as the tool exits the main bore.

The tool body shows a recess in the feed direction. This prevents the burrs from being pushed down or bent into the cross bore in advance.

Extra long tools are usually assembled (multi-piece construction) and require an adequate guidance in the main bore direction as well as a generously dimensioned chamfer. It is strongly recommended not to activate the tool without guidance.