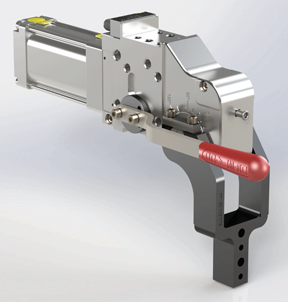

DE-STA-CO 82M-3E pneumatic power clamps

82M-3E Series of enclosed pneumatic power clamps from DE-STA-CO provide automotive and sheet metal processing customers with superior holding power in a versatile, user-friendly and low-maintenance package.

This full line of lightweight aluminum power clamps includes four sizes: 40mm, 50mm, 63mm and 80mm. The 82M-3E Series is well suited for a number of applications, including manual and automated fixture welding, positioning and locating.

All of DE-STA-CO’s 82M-3E Series power clamps feature infinite arm opening adjustment with the industry’s greatest opening angle range: from 0 to 135 degrees. This provides system integrators with maximum flexibility. The angle is easily adjusted in just seconds from behind the clamp. Not only does this patent-pending design feature save time, it also means 82M-3E power clamps require less space, allowing fixtures in which they’re installed to be lighter and more ergonomic than those equipped with other clamps. The 82M-3E’s sensors never need adjustment, even when the opening angle is changed, providing additional time savings.

Each of the 82M-3E Series clamps is available with a patent-pending hand lever on the right or left side for applications requiring manual loading. The levers feature the distinctive DE-STA-CO red handle and are adjustable for improved ergonomics.

To provide long life with minimal maintenance, each 82M-3E Series clamp features an enclosed body, sealed needle bearings and a completely enclosed sensor to prevent the intrusion of dust or debris. Repairs are simplified by the sensor cartridge’s two-part design, which makes it possible to replace only the damaged component instead of the entire cartridge.

“Developing a new family of power clamps gave us the opportunity to step back and look at the product from the customer’s perspective,” explains Peter Schauss, DE-STA-CO global product director for power clamps. “As a result, we’ve come up with a best-in-class series of clamps that is flexible and easy for integrators to set up, and that will perform for the end user customer over millions of cycles with minimal maintenance.”