EdgeWise plant streamlines digital twin generation workflows

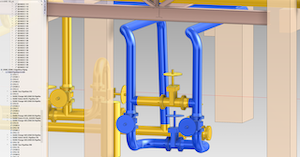

ClearEdge3D, a trailblazer in software solutions for the architecture, engineering, and construction (AEC) industry, has announced the availability of EdgeWise Plant — an accurate, efficient as-built modeling platform that reduces time and potential errors associated with manual modeling techniques. The platform is the first automated modeling solution fully integrated with AVEVA E3D Design and AutoDesk Plant 3D.

“Our goal with designing EdgeWise Plant is to offer a faster alternative to brownfield digital twin generation workflows, which are tedious and time consuming,” said Justin Dommer, EdgeWise product manager at ClearEdge3D. “This platform will simplify as-built modeling for industrial, marine and process professionals, allowing them to focus on tasks of greater value-add.”

EdgeWise Plant integrates seamlessly with AVEVA E3D Design, allowing users to automatically model piping and structures and then import them into E3D as a native PML script. Once imported, elements are automatically organized according to the project hierarchy, representing piping as organized equipment and sub-equipment, directly mapped to their respective systems. The new Catalogue Importer in EdgeWise Plant enables easy import of any structural catalog, ensuring that structures come through as native GENSEC elements created directly from E3D steel catalogs, preserving full data intelligence and continuity between platforms.

Edgewise Plant uses robust QA/QC tools to confirm that piping and intelligent structures accurately fit in the model, and allows users to make adjustments or resize objects as needed.

With advanced computer vision and pattern matching technologies, EdgeWise Plant offers quick automated modeling using mobile data, along with more flexible and complete as-built modeling. Users can easily change scan data types without learning new workflows. They can also import previously cleaned or clipped point clouds.

EdgeWise Plant works in five simple steps:

1. Load the register point cloud into EdgeWise Plant

2. Extract piping and structure through the software’s computer vision and pattern matching algorithms

3. QA/QC tools verify the accuracy of extracted elements

4. Semi-automated finishing tools complete the model

5. Export the model to AVEVA E3D Design or Autodesk Plant 3D