Say hello to your old friend, Mr. Pareto

The challenges of distribution center design

by Howard Coleman, MCA Associates

Maybe you know this story; Italian economist Vilfredo Pareto observed in 1906 that 80% of the land in Italy was owned by 20% of the population. Then business management thinker, Joseph Juran, developed the “80/20” principle and named it after Pareto by observing that 20% of the pea pods in his garden yielded 80% of the peas. Now, this holds true across a wide swath of occurrences; 20% of your customers probably account for 80% of your sales, 80% of your HR problems might come from 20% of your workforce, etc.

Maybe you know this story; Italian economist Vilfredo Pareto observed in 1906 that 80% of the land in Italy was owned by 20% of the population. Then business management thinker, Joseph Juran, developed the “80/20” principle and named it after Pareto by observing that 20% of the pea pods in his garden yielded 80% of the peas. Now, this holds true across a wide swath of occurrences; 20% of your customers probably account for 80% of your sales, 80% of your HR problems might come from 20% of your workforce, etc.

So, as it turns out, there is a great deal of similarity between pea pods and your distribution business!

Point: Only 20% of your SKUs make up 80% of your volume.

Single method and technology distribution systems assume that all products should be handled in the same way. But, here is an instance where such a balance is not always good!

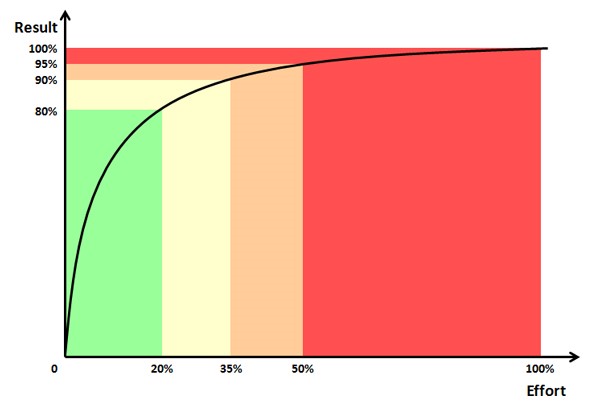

Mr. Pareto would suggest that we should apply different technologies, different methods, to the different SKU segments that generate 80% of the business. In other words, apply multiple technologies to optimize the efficiency within the different “bandwidths” of the Pareto Curve.

So Why Do We Continue With Single Methods & Technology?

So, what does this have to do with your distribution center design? When I mentioned single-technology distribution systems, I meant do you pick all your SKUs using the same method? If so, you may be missing out on some huge opportunities for efficiency, productivity improvement and lower costs. In other words, you can leverage the different bandwidths in this Pareto Curve by applying some smart design, methods and technology.

Doesn’t everybody already know about the Pareto Curve? And, if they do know, why do they continue with only one piece of the puzzle? I can tell you for sure that there are a lot of folks who don’t know about the Pareto Curve and how it really affects their distribution center. So, in other words, either through ignorance or lack of curiosity, the opportunity for change management never does get on the table.

Now granted, some distribution centers may be just outdated. They may operate within the confines of a lot of manual solutions (their own single technology systems). Often, that technology is people, an army of people (“walkers”) trudging through the distribution center with carts and forklifts, armed with that one technology.

I’ve said it many times in my articles and presentations; 70% of a picker's time is spent walking, 30% of the time is spent actually picking. Out of an 8-hour day, that’s less than 2-1/2 hours of actual picking! Not good!

Picking Strategies vs. the Pareto Curve

Utilizing Pareto, we have the opportunity to assure that our pickers don’t have to pass up to 80% of the SKUs to find the ones they want.

To do this, you can employ a variety of methods and technologies, each meant to reduce walk time:

- High Velocity Pick Zones

- Narrow Aisle Storage & Picking Zones

- Carousels (bringing product to the picker)

- Zone picking

- Batch and/or Wave picking

Each of these specific options reduces the percentage of time walking, and conversely increases actual productive picking time.

A few more words regarding well executed “High Velocity Pick Zones” previously mentioned and pictured at right. The principle is quite simple; concentrate the fast-moving, frequently-touched SKUs in a single area, maybe even its own picking zone. Think of it like the “penthouse residents” versus the “basement dwellers” (you know, those slower moving SKUs that often reside in the same building). If you’ve ever done a Pareto Analysis you’ve found that relatively few SKUs in your distribution center or warehouse account for a high percentage of picks (order hits). Time and time again, I find that at the typical wholesale distributor with 10,000 to 15,000 SKUs, 20% to 50% of the hits are represented by just 500 to 1,700 SKUs, those that we sometimes call the A items. The numbers don’t always conform exactly to 80/20, but you get the point of the principle, I’m sure.

A few more words regarding well executed “High Velocity Pick Zones” previously mentioned and pictured at right. The principle is quite simple; concentrate the fast-moving, frequently-touched SKUs in a single area, maybe even its own picking zone. Think of it like the “penthouse residents” versus the “basement dwellers” (you know, those slower moving SKUs that often reside in the same building). If you’ve ever done a Pareto Analysis you’ve found that relatively few SKUs in your distribution center or warehouse account for a high percentage of picks (order hits). Time and time again, I find that at the typical wholesale distributor with 10,000 to 15,000 SKUs, 20% to 50% of the hits are represented by just 500 to 1,700 SKUs, those that we sometimes call the A items. The numbers don’t always conform exactly to 80/20, but you get the point of the principle, I’m sure.

Summary

Leveraging this imbalance is an opportunity to force tremendous change and productivity benefits as well as improvement in your operational cost metrics. But also recognize that you will not only need multiple methods and technology but probably some updated materials storage media, materials handling and conveyance equipment, as well as having different work processes in place to address those different bandwidths all along that Pareto Curve. This could include flow-racking, narrow aisle storage, conveyors, etc.

Finally; some additional tips…

Get help from a distribution center/warehouse design partner, one who can analyze your distribution center, its products, your current WMS technology utilization, the through-put needs now and into the foreseeable future, and can integrate it all into a design roadmap with you.

- Look for a partner that focuses on “future cost avoidance” opportunities

- Provide them all the information and data they request, so they can do the analytics, develop the concepts and propose a solid design

- Look for a partner that can not only recommend process change, but is also skilled in change management

- Look for a partner that can help you develop the appropriate performance metrics to measure your progress toward continuous improvement

So, if you are already familiar with the Pareto Curve, say hello to your old friend. If not, say hello to your new friend, Mr. Pareto!

Howard W. Coleman is principal of MCA Associates, Derby, Conn. Reach him at (203) 732-0603 or hcoleman@mcaassociates.com or online at www.mcaassociates.com.

MCA Associates is a management consulting firm that works with wholesale distribution and manufacturing companies that seek and are committed to operational excellence. Its staff of senior consultants provides operational excellence – thought leadership - and implements continuous improvement solutions focused on business processes, inventory and supply chain management, distribution center/warehouse design and productivity improvement, sales development and revenue generation, information systems and technology, and organizational assessment and development including family-business succession planning.