Product Variety and Value Trump Price

|

|

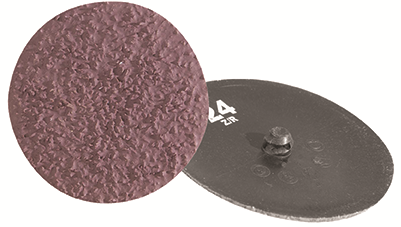

Patented and trademarked abrasives from Gemtex |

Wide opportunity for distributors to consult on evolving, complex customer applications.

Customers are demanding more from grinding wheels, whether to compensate for a less experienced workforce or to step up into the challenges of new and expanding applications. Relationships are in the hands of the distributor, and manufacturers are supporting them with product range, advancements, and innovations to support that consultative role.

GEMTEX ABRASIVES

Global manufacturers in the automotive and airline industries are aggressively searching for abrasive vendors able to provide a broad range of their abrasive products to minimize the vendors needed to accomplish their grinding and finishing applications. It is critical for abrasive manufacturing companies to recognize these end-user demands and to work closely with their distribution partners to provide a wide variety of product types needed — as well as the newest technologies available — for them to enhance their productivity.

|

| Prenda |

“As a coated abrasive manufacturer, Gemtex Abrasives provides unique products which are patented or trademarked by Gemtex, such as the Trim-Kut trimmable grinding disc with multiple mounting options and Mini Grind RTR one-piece plastic-back type R style,” said Frank Prenda, vice president of sales and marketing. “In addition, we have utilized adaptive engineering to enhance long standing product categories, such as 2 Ply Mini cloth quick change discs, into enhanced versions using globally-sourced raw materials. The goal is three-fold: (A) the product category is enhanced, (B) Gemtex provides a competitive price and (C) the end-user is able to consolidate their abrasive suppliers.”

The non-woven abrasive category is approximately USD 1.5 billion and is expected to grow 5.5% CAGR from 2024-2032. This category includes surface conditioning products which is one of Gemtex’s fastest growing product segments over the past two years due to the fact end-users are constantly striving to improve surface finishes with products that provide specified quality results at a high efficiency rate.

|

To meet those demands, Gemtex has invested in additional machinery to expand its manufacturing capacity in surface conditioning products as well as its Flaptec line of flap discs and the Brite Prep line of striping discs.

“Abrasives are constantly evolving as manufacturers, like Gemtex, strive to meet the ever-changing application complexities. If you listen to the customer, they will tell you what they are looking to accomplish. It is up to us, to provide what they need!”

BUFFALO ABRASIVES

There used to be a time when the industry was primarily focused on the quality of the product and gaining market share. Today, many other variables come into play such as labor and aging machinery being used. As a manufacturer, Buffalo Abrasives says it’s finding the request isn’t so much the specific price of the product, however an important consideration but rather the way the value of the product is being measured.

|

| Pigeon |

“We have always been a manufacturer that specializes in nonstandard – not off the shelf type of product,” said Kimberly Pigeon, sales and marketing manager. “However, we are experiencing opportunities brought to us from the field, not just to make the ‘wheel’ but to help increase production and enhance the application they have been doing for years. Most of the time with the same machines used for decades. Unfortunately, the skill set of many companies has been lost and customers are looking for the wheel to do more of the work with an unskilled worker or to allow the skilled grinder to accomplish more.

“I was once told that if a manufacturing company isn’t reviewing all their applications approximately every five years, they are behind. Partnering with distribution that has the relationships along with our technical support to develop a specific wheel is becoming more and more of our business. Our development team is constantly working on the use of new grains, resins, bonds, etc.”

Older machines can’t always make the set-up adjustments needed to accomplish the goal, many times it’s the grinding wheel that needs to be modified to adjust to feeds or speeds. There are many new exotic materials in today’s market, all of these require nonconventional ways to remove material or obtain the finish, thus looking at new bonds to address things such as heat, loading, finishing, dressing systems and holding form are a few of the areas of consideration.

|

“You can’t be looking to be the same as, but rather looking to be better than the competition,” said Pigeon. “And this is what customers are looking for as well. What’s required is communication between the customer, distributor and manufacturer to improve an application and then to back it up with local support and service. You must listen to all involved with the process and build a customized solution. You just can’t always secure business trying to fit a square peg into a round hole!”

NORTON | SAINT-GOBAIN ABRASIVES

Today’s competitive abrasives market, more demanding grinding requirements, and advancements in abrasive technology are driving abrasives product development.

|

| Spencer |

“We, like other abrasives manufacturers, are always researching ways to develop a new product to meet new grinding requirements,” said Jeremy Spencer, product manager. “Customers benefit by having new abrasives solutions, some that may initially have a higher price, but when factoring in life and performance, overall process costs are lower. New abrasive products are designed with the operator and process in mind, allowing operators to grind longer with ergonomic, easier-to-use solutions so they can quickly complete their task and move on to the next process. The latest abrasives remove more metal faster, last longer and also extend the life of the right-angle grinder.”

Responding to marketplace trends and customer demand, Norton | Saint-Gobain has invested capital into the industry’s most comprehensive robotic cell so that its Abrasives Process Solutions (APS) team can work with customers to help them automate manual processes. Companies exploring automation are often concerned about the upfront cost and whether the automation solution will work, according to Spencer. By working with Norton, he adds, customers can provide their workpieces, for the Norton APS team to validate a process and provide a proven solution. Customers do not have any financial risk and do not have to stop their own in-house production.

On the new technologies front, Norton has introduced this January its RazorStar for belts, fiber, and quick-change applications.

“This new product is a true advancement in abrasives technology, featuring innovative engineered shaped ceramic grain,” said Spencer. “It improves safety by allowing operators to let the abrasive do the cutting versus having to apply force. Testing has proven RazorStar has two times better cutting performance than other ceramic discs on the market today, offering improved life and more value per part.”

|

| RazorStar Fiber Discs are available in sizes ranging from 4.5 to 9 inches in 7/8 hole, speedchanrge, and AVOS discs. |

Designed for medium- to high-pressure metal removal in challenging robotic or off-hand applications, RazorStar is producing the same number of parts with fewer belts and less machining and changeover time, while consuming less energy, added John Benkoczy, senior product manager. The new RazorStar Fiber Discs, Quick-Change Discs and Belts are offered in 36-grit: RazorStar Fiber Discs are available in sizes ranging from 4.5 to 9 inches in 7/8 hole, speed-change, and AVOS discs. Key markets include MRO, metal fabrication, welding, oil and gas, energy and ship building. RazorStar Quick-Change Discs, which are available in two and three inch sizes, feature a strong backing that stands up to extreme pressure when removing stock, deburring, beveling and blending, and are especially well suited for aerospace, MRO, metal fabrication, welding and energy industry applications.

Norton also recently released several new non-woven products that are more aggressive but leave a finish that, for most applications, is still acceptable as the final step. Vortex Coarse Grit Unified Wheels, Coarse Grit High-Strength, and Vortex Flap Discs have the ability to remove defects and finish in one step. Reducing steps is the best way to reduce overall costs versus just evaluating the cost of the abrasive.

Looking ahead, Spencer says advancements in grain technology and resins will continue to allow Norton Abrasives to create new products that will reduce steps and improve performance for customer applications. Coarser products on lighter backings, and finer grits with extended life are already being developed and released. “The future is sharp for abrasive consumers,” he said.

This article originally appeared in the January/February 2024 issue of Industrial Supply magazine. Copyright 2024, Direct Business Media.