Versatility drives reels market

by Rich Vurva

The need for greater versatility and customizable solutions is driving new product development for hose reel manufacturers. Some end-users are looking for reels to transport larger hoses that can handle higher fluid output while others require reels that fit in tighter spaces. Here’s how reel manufacturers are keeping up with ever-changing customer requirements.

Coxreels

Coxreels

“Coxreels is at the forefront of new technology development and innovation in the hose reel industry,” says Florent Antonetti, marketing manager for the Tempe, Ariz.-based manufacturer. “Our pioneering heritage has led to the development of improved hose reel features and benefits while keeping operator safety and product maintenance in mind. We have responded to these customer demands and market trends by developing new products, revamping existing products and introducing new reel accessories.”

The new 1600 Series reel offers components in multiple configurations and sizes, offering customers a robust “build it your way” platform for any conceivable application. The versatile foot print of the 1600 Series reels enables end-users to fit allocated reel space in all equipment.

“We recently improved existing products and re-engineered the fluid path and outlet riser on the 1175, 1185 and 1195 Series for maximum product flow. These three existing series have been enhanced and now come equipped with a remodeled low-profile outlet riser offering improved full-flow characteristics,” he says. The reels handle 1-inch and 1 1/2-inch hose I.D. and work well in high-flow watering and high-volume fluid delivery applications.

Antonetti adds that Coxreels recently introduced the first of its kind hose strain relief kit for hose reels. This accessory protects the hose fittings and connections from potential damage by providing strain relief when the hose is fully extended on the reel. “With the mounted strain relief kit, the hose remains secured against the drum, allowing the hose to be routed between the riser connection and the clamp with a proper bend radius, minimizing the opportunity for the hose to strain,” he says

Hannay reels

Hannay reels

While reels have always been used for a variety of different applications, in today’s market they need to fit in tighter spaces, special compartments or adapt to a new fluid. More reels are being installed on utility vehicles, trucks and portable units, so they need to conform to the space provided, which is never the same from one unit to another, says Jennifer Wing, marketing manager for Hannay Reels in Westerlo, N.Y.

Hannay relies heavily on feedback from distributors, dealers and OEM accounts to keep up with customer requirements. “They are the front lines on communicating new applications or just changing trends in existing markets that can affect where R&D efforts go,” Wing says. While many hose reel markets are mature, new ones can and do spring up every few years, such as the rapid growth of reels for dispensing diesel emissions fluid (DEF), or the desire on the part of many OEMs that purchase electric motor rewind reels to lessen their labor costs by purchasing reels where some electrical components have already been mounted and pre-wired.

Steel, stainless steel or aluminum construction are still the materials of choice for reel construction where durability is paramount. “The trick is finding the right balance between strength, weight and cost,” she adds. Good design choices, including the use of structural channel with a high strength-to-weight ratio, and investing in tooling that allows the production of durable formed stampings, give the discs and frames high rigidity while keeping the overall weight reasonable. For corrosion resistance, steel components can be individually electro-coated prior to assembly and paint. For particularly harsh environments, aluminum and especially 300-grade stainless steel are the best options, she says.

What might drive reels of the future? “Better and more reliable rewind technology, such as improved motors and new controls for governing rewind and unwind speed, will continue to be developed. Easier, quicker serviceability is also a major design goal, especially for any component on a reel that will naturally wear or need to be replaced at some point, such as a spring rewind locking device, or a swivel joint O-ring seal,” she concludes.

Reelcraft

Reelcraft

The market is demanding a wider selection of products within an application range, says Bill Martin, national sales manager for Reelcraft, based in Columbia City, Ind.

“Customers want choices of price points with matching quality depending upon the severity of their application or budget constraints. The days of one size fits all are clearly a thing of the past.”

Martin says Reelcraft has developed an extensive product line using a Good-Better-Best approach, plus Ultimate Mobile Equipment Mount spring driven hose reels that cover a wide range of specific application requirements.

For the value conscious buyer, Reelcraft’s Series RT is a hybrid hose reel designed for strength and lighter weight. The ratchet lock is built into the guide arm for easy access and is operated by a long lasting torsion spring, providing extended service life and ease of maintenance. This series is available for air, oil, grease and nitrogen applications.

On the opposite end of the product spectrum, Reelcraft engineers more recently developed Series DP5000, DP7000 and SD10000 Dual Pedestal hose reels for the most demanding applications. They are lower profile by design to fit into cabinets where space is at a premium or in any demanding in-plant application.

“These rugged models feature an innovative interlocking dual base for strength and vibration resistance and a long-life guide arm-mounted latching mechanism that is also operated by a long-life torsion spring. To insure the reliability of the series DP models prior to their introduction, they were tested and met or exceeded the military vibration for Truck Transport test MIL-STD-810F, 500,000 mile equivalent. Both the Series DP and SD have been well received in the market due to their compactness and proven reliability,” Martin says.

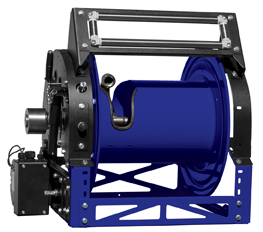

For customers who need reels for larger and longer hoses, Reelcraft introduced a full line of large frame hose reels offered in standard hand rewind or motor driven models for hoses up to 4-inch I.D. and up to 350 feet in length. Standard models are available for many markets and Reelcraft engineers have the capability to custom build reels to the customer’s specifications.

Reelcraft just introduced an all new Series LC spring-driven stainless steel value oriented hose reel for 3/8-inch x 70-foot or 1/2-inch x 50-foot I.D. hoses. They are ideal for the food processing, commercial kitchen and many other markets that require a sanitary or corrosion-resistant hose reel. They also have many features that ensure long service life, Martin says.