Smart Technologies: Friend or money pit?

by Dick Friedman

The rather simple 100-plus year old pallet is about to become “smart,” joining a host of other technologies that have always been smart. Depending on the specifics of a warehouse, some smart technologies can help industrial distributors increase

productivity or reduce mistakes.

However, most technologies are expensive, but benefits are not guaranteed. After summarily describing some smart technologies, we will look at the steps to take to determine if a technology should be obtained.

A Cornucopia of Technologies

Powered by batteries, the low-cost smart pallet being developed by GM is designed to carry items from one section of a warehouse on to a truck, and at the customer’s site, travel to wherever the items are needed. A press release lists a 200 lb. capacity and 3 mph speed.

Initially, a human will control the smart pallet, but a future version would be automatically controlled, like the AGV described below.

Radio Frequency IDentification (RFID) refers to a computer chip that can be affixed to a carton or pallet-wrap or a piece, and in which much data can be stored (for example, date of manufacture); special readers can read the data, even if a chip is not in the line of sight or is hidden by a carton. However, the cost per chip is still prohibitive, as is the cost of special data write/read devices.

The Internet of Things (IoT) refers to assigning a unique Internet address (IP address) to a device that acquires and/or transmits data (a dedicated sensor), and/or controls something (such as the power to an automated conveyor belt). IoT-enabled devices can be programmed and controlled via the Internet, and are just being adapted for warehouse use, resulting in the “connected warehouse.”

Automated Guided Vehicles (AGV) are wheeled, powered product-moving machines. Until recently, they were controlled by signals that special warehouse software transmitted to wires buried in a warehouse floor. Burying wires is an expensive process, and buried wires cannot be relocated as the product-mix, volumes and storage arrangement change. Now, thanks to IoT and other technologies, wires are no longer needed, so remote-controlled forklifts are now termed “autonomous forklifts.”

One example of an Automated Storage and Retrieval System (ASRS) is a set of bins that move like the steps of an escalator, only the handrails are vertical and the bins pivot on end-rods and so always remain horizontal. At the command of a worker, the ERP system transmits data to a power-controller, which in turn rotates the bins so that the needed bin is at eye level (for picking or putting away). Another example looks like a multi-story carousel of bins, and at the command of a worker, it rotates the needed column of bins to face the worker (who reaches out or up or down to get at the needed bin). Both types save floor space.

Product is usually loaded onto or taken from an ASRS by people, but newer versions of ASRS can be wirelessly connected to a single-arm robot so product can automatically be loaded onto or taken from the ASRS. This arrangement improves productivity because a robot arm does not have to wait for a bin or shelf to move to worker-reachable height. Even without ASRS, a single-arm robot can be attached to a vertical shaft that is attached to a post of a stationary shelving unit, and move up, down and over to pick products and place them in totes or cartons or dollies; and robots can put away products.

Mobile robots can slide under portable shelving units (filled with picked product), and move the shelving to sorting/staging/packing areas where people make the final decisions. Similarly, these robots can move received product to put-away locations. In an effort to advance the use of not-so-cheap robots, at least one manufacturer now offers to rent them.

Several companies are experimenting with using drones to move small, light-weight products from delivery trucks into customers’ job sites – the so called “last mile” challenge. But drones are already being used by some companies in their warehouses and storage yards for cycle counting and other inventory monitoring activities; some companies are experimenting with using drones to pick small, light-weight products, and take the products to a sorting/staging/packing area. So far, a human, not software, controls each drone.

Image-based bar code readers allow reading a bar code no matter the direction in which a code is scanned. And these special readers can scan 2-dimensional bar codes, which have been around for a while and contain much more information than traditional bar codes – but not as much as RFID chips.

Warehouse Management System (WMS) refers to a distinct software package that is interconnected to the ERP system, and is used to: verify the validity of received items; determine where to put away received items that do not have permanent bin assignments; track the quantity on hand of each item in each bin location; alert users when pick areas need replenishing; generate pick tickets or data for

RF displays; verify the accuracy of picking, packing and loading; generate truck manifests; suggest changing the arrangement of items with permanent bin assignments (as item velocities change); track picker productivity; compare picker productivity to management-defined standards.

Voice Directed Picking (VDP) refers to a system in which each user wears a device that he or she has “taught” to recognize his/her speech patterns. To each device is attached earphones and a microphone. The main ERP system transmits to the VDP server data about each order ready to pick and the VDP server stores this data. The VDP software determines which people are available at any time, then transmits data to a specific user device. The device transforms the data into that user’s voice, telling him/her the location to go to, the SKU number involved and the quantity. The user then does the picking and “tells” his/her device the SKU number involved and the quantity and task performed; the speech is transformed into data, which is transmitted by the VDP server back to the main system (for verification).

A similar sequence of steps is used for put away – the system tells the user where to go and how much to put into the directed location; the user tells the system what item was put away, the slot location and the quantity.

Is It Likely To Be Worth the Cost?

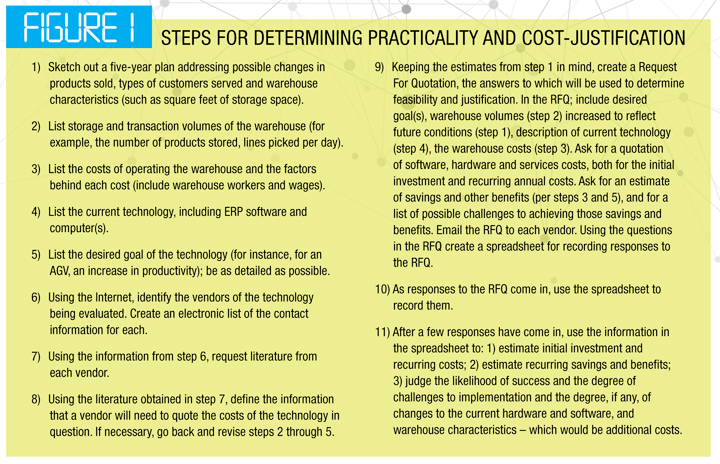

Although different technologies have different characteristics, the steps outlined in Figure 1 can be applied to determining the potential practicality and cost-justification of any of them.

Dick Friedman is a Certified Management Consultant who does not sell any technology nor necessarily endorse using any. For 40 years he has objectively helped industrial distributors determine if a particular technology should or should not be obtained. For worthwhile technologies, Dick helps obtain them, including negotiating contracts that protect the distributors. He also helps distributors prevent warehouse mistakes that lose sales and customers; even distributors using bar codes. For a FREE consultation contact him via www.GenGusCon.com.

Dick Friedman is a Certified Management Consultant who does not sell any technology nor necessarily endorse using any. For 40 years he has objectively helped industrial distributors determine if a particular technology should or should not be obtained. For worthwhile technologies, Dick helps obtain them, including negotiating contracts that protect the distributors. He also helps distributors prevent warehouse mistakes that lose sales and customers; even distributors using bar codes. For a FREE consultation contact him via www.GenGusCon.com.

This article originally appeared in the May/June 2021 issue of Industrial Supply magazine. Copyright 2021, Direct Business Media.