Don't lose your head

by Saneel Khopkar and Sharmila Mudgal

The human skull does a fairly good job of protecting your brain, eyes, ears and nose, but it has its limitations. The force of a hard object falling on your head can easily fracture your skull or penetrate your dense skull bones. Most impact head injuries are very serious. Even if they don’t cause a fracture, they can still cause a concussion.

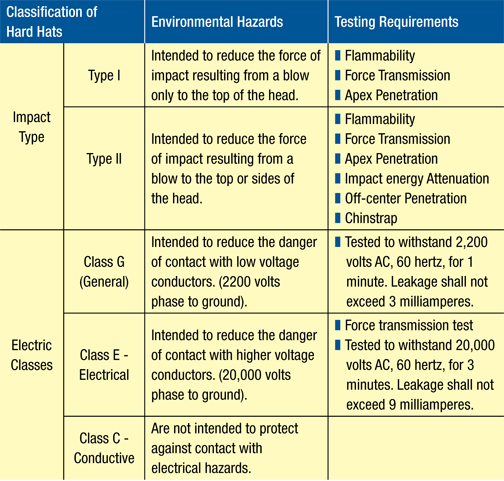

Hard hats are used to prevent injury to the head from falling objects, impact and penetration hazards, electric shock, burn hazards and injuries due to a strike from low- hanging overhead objects. Safety standards of hard hats are regulated by OSHA 29 CFR 1915.155(b)(1) and (b)(2) and set by the American National Standards Institute for Industrial Head Protection, ANSI/ISEA Z89.1-2014 standard. (Canadian Standards “Industrial protective headwear - Performance, selection, care, and use” CSA Standard Z94.1-15) (Indian standards Specification for Industrial Safety Helmets – IS 2925). These standards establish different types and classes of hard hats.

Hard hats consist of an outer shell and harness/suspension system. The shell is the hard covering, rounded in shape to protect the crown of the head. A harness/suspension system is used to prevent the hat from falling and keeps it securely fastened.

When used correctly, the shell and suspension system work in tandem to absorb the force from an impact to the head. Hard hats must be made from water-resistant and slow-burning material. Different materials are used in different parts of the hard hat PPE. The materials used in the outer shell are:

ABS - Acrylonitrile Butadiene Styrene. ABS is an impact-resistant engineering thermoplastic and amorphous polymer.

HDPE - High-density polyethylene is a thermoplastic polymer with a high strength-to-density ratio.

Materials used in the chinstrap, padding and suspension plastic lock pin are a combination of linear low-density polyethylene (LLDP) which has high flexibility and ductility; HDPE and fabrics like nylon plus polyethylene. Sweat pads are made of washable and high durability polyethylene like low-density polyethylene (LDPE), which is a soft, flexible, lightweight plastic material.

The current market trends for safety headgear are showing an increasing demand for:

1) Comfort and Fit – As these helmets are meant to be worn for extended periods a comfortable and well-fitting helmet is the main USP employers want in their helmets.

2) Lightweight material – The helmets should not be heavy enough to cause a strain on the wearer’s neck and must be light enough to accommodate the average moments of a human’s head and neck without causing undue stress.

3) Multicolor – Having helmets coded in different colors makes it easier to recognize separate departments of workers at a glance and is good for management and productivity.

4) Decals – Custom-made decals that identify the industry or company logo and segregate the types of workers on the floor are also in high demand. They not only help the management of the worker but also develop brand value and loyalty.

5) Head-mounted brackets for lights/reflective panels – Very useful for dark environments nightshift workers providing a hands-free lighting solution.

6) Cross Compatibility – Provisions made for different accessories that can be fitted into hard hats like an eye shield, face shield, welding shield, a wide brim for additional shade in hot climates, a lining for cold conditions, and earmuffs/other ear protective devices.

7) Communication – Provisions for communication devices that can be added as a part of the helmet frame or external devices.

8) Ventilation (powered) – Provisions for non-powered vents in the helmet which will work when there is external air breeze and for a fan-powered air circulation system that can work in absence of an external breeze.

Saneel Khopkar, MB, BS, MPH, is a research analyst-epidemiologist specializing in injury prevention; and Sharmila Mudgal, MD, medical director, Venus Safety & Health USA.

This article originally appeared in the Sept./Oct. 2021 issue of Industrial Supply magazine. Copyright 2021, Direct Business Media.