Allied Machine to launch T-A Pro drilling system

Allied Machine and Engineering announced the launch of its high-penetration drilling system, the T-A Pro.

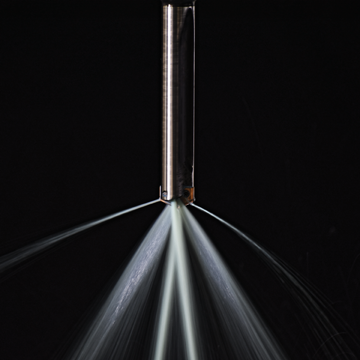

The T-A Pro drill combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system to allow penetration rates which run at speeds nearly 30 percent faster than other high performance drills on the market. Coolant outlets are designed to direct maximum flow to the cutting edge providing quick heat extraction where it is most critical - even at significantly higher speeds. Material-specific insert geometries produce impeccable chip formation and the drill body incorporates straight flutes redesigned for maximum coolant flow and excellent rigidity. These design elements combine to extend tool life, create consistent quality holes, and provide superior chip evacuation. As a result, the T-A Pro drill offers machine shops and high production manufacturers a spade drill with incredible speed and a cost per hole averaging 25 percent less than existing drills.

The T-A Pro drill combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system to allow penetration rates which run at speeds nearly 30 percent faster than other high performance drills on the market. Coolant outlets are designed to direct maximum flow to the cutting edge providing quick heat extraction where it is most critical - even at significantly higher speeds. Material-specific insert geometries produce impeccable chip formation and the drill body incorporates straight flutes redesigned for maximum coolant flow and excellent rigidity. These design elements combine to extend tool life, create consistent quality holes, and provide superior chip evacuation. As a result, the T-A Pro drill offers machine shops and high production manufacturers a spade drill with incredible speed and a cost per hole averaging 25 percent less than existing drills.

The T-A Pro drilling system will be available in diameters ranging from 0.4370” – 1.882” (11.1mm – 47.80mm) and is ideal for holes ranging in stub, 3xD, 5xD, 7xD, 10xD, 12xD, and 15xD depths. The drill will be stocked in both imperial and metric shanks, with flat and cylindrical variants. The carbide insert geometries offered initially will cater to the following ISO material classes:

- Steel (P) with AM300 coating

- Cast iron (K), with TiAlN coating

- Non-ferrous (N) with TiCN coating

“The T-A Pro drill is designed for use in applications ranging well beyond general purpose drilling. It truly will target all industries, offering phenomenal tool life at high penetration rates, especially in situations where the balance of chip formation at high penetration is critical,” said Sal Deluca, product manager.