Dehumidification systems for lithium-ion battery industry

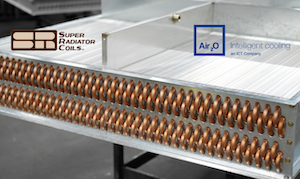

Air2O, a global leader in advanced thermal management solutions to mission-critical environments, is pleased to announce a new partnership with , a leading manufacturer of coils, heat exchangers, and nuclear products engineered for use in technologically sophisticated cooling and heating applications.

Air2O awarded Super Radiator Coils a $2 million contract to supply custom-engineered fluid coils for its extreme low humidity (ELH) units being manufactured for a lithium-ion battery production facility currently under construction in the Midwest. Air2O ELH solutions are engineered to meet the lithium-ion battery industry’s stringent low dew point requirements, providing unparalleled environmental control precision. With custom-built capabilities and advanced, sustainable technologies, Air2O delivers the most efficient and optimal solutions for clients around the world. It is the sole manufacturer of low dew point HVACD applications in Arizona.

“Super Radiator Coils has the technical and manufacturing capabilities to take a design from engineering through production at any of its U.S. facilities,” said Michael Sullivan, CEO of Air2O. “Their research and development expertise, onsite testing labs, supply chain relationships, and ability to ramp up to support this build in an exceptionally tight timeframe made them the perfect partner to help us deliver efficient industrial thermal management solutions to one of the fastest-growing industries in the world.”

Both companies have engineering and production facilities in Phoenix, enhancing collaboration, streamlining the supply chain, and speeding time to market.

“We collaborated with Air2O’s engineering team to develop 26 fluid coil designs for five different types of Air20 units. The largest is 7.5 feet tall, 10 feet wide, and weighs just under a ton,” said Tyler Johnson, vice president of the Phoenix division of Super Radiator Coils. “These high-performance heat transfer products are being manufactured in our Arizona and Minnesota facilities to ensure delivery to Air2O at the precise time needed during their build process.”

“We are committed to our outstanding global suppliers, but the opportunity to work with Super Radiator Coils in the U.S. is a win-win-win for both companies and our clients,” Sullivan said. “We share expertise in many of the sectors we serve, including industrial manufacturing, data centers and semiconductor manufacturing, and, of course, battery production. We look forward to working with them on a variety of next-generation systems for Air2O customers.”

The companies also share a dedication to developing manufacturing in Arizona. Air2O moved its global headquarters to Arizona in 2017 and opened its first manufacturing facility in the state in 2020. “The Arizona Commerce Authority and Greater Phoenix Economic Council have led the way in Arizona, creating more opportunities for growth for companies like ours,” Sullivan said. Air2O is a member of both.

Super Radiator Coils has tripled in size over the past several years and is actively looking for in-state plant expansion opportunities to allow for continued growth. “There is an incredible amount of engineering, fabrication, and manufacturing talent in the state,” said Johnson. “We are proud to be a part of a business and manufacturing community that is opening up educational and career opportunities for people with skills that are in demand across a variety of industries.”