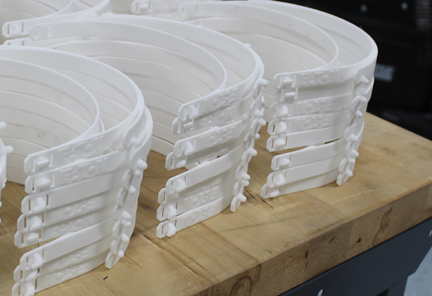

Eaton uses 3D printing to produce face shields for COVID fight

Eaton is using its manufacturing, 3D printing expertise and partner network to fulfill a JobsOhio order for rapid production of 360,000 reusable face shields to strengthen the state’s fight against the COVID-19 virus.

Eaton collaborated with multiple hospitals and Cleveland’s Manufacturing Advocacy and Growth Network (MAGNET) to optimize the face shield design for production. Now, Eaton is working with Thogus, a local family-owned custom plastic injection molder, to rapidly produce the critical equipment at scale.

Eaton collaborated with multiple hospitals and Cleveland’s Manufacturing Advocacy and Growth Network (MAGNET) to optimize the face shield design for production. Now, Eaton is working with Thogus, a local family-owned custom plastic injection molder, to rapidly produce the critical equipment at scale.

“Ten business days ago, this project was just a concept. Today, we’re moving forward with production and looking to expand further,” said Michael Regelski, senior vice president and chief technology officer, Electrical Sector at Eaton. “By leveraging our advanced manufacturing capabilities and strong network of partners, we’re helping Ohio quickly respond to current inventory challenges and maximize accessibility of critical PPE resources for front line teams combatting COVID-19.”