Specialists in the Post-Recession Economy

Here's what you can do today to prepare for better days ahead

by Frank Hurtte

Whether it’s the talking heads of TV’s nightly news or the blaring blog posts zooming through cyberspace, the news is pretty much the same. Economists are lauding the end of the Great Recession. For us foot soldiers in the trenches, the end of the war seems less pronounced. Bullets are still singing their deadly tune just over our head; we continue to hear of comrades lost in smaller but still deadly resizing. But, the big picture report continues to slowly trend upward. It appears we will win the war against the recession.

Life after the war will be markedly different. What might this brave new world look like? More importantly, what can a distributor specialist do to prepare for the coming times?

Recessions are accelerators. Business trends hanging in the background gain speed and reach a crescendo immediately following recessions. Examples exist from past economic downturns. Right-sizing, re-engineering, JIT inventory, supply contracts and integrated supply agreements exploded onto the scene following recessions in the past couple of decades. They rose from obscurity, gained traction and spread like a virus across our environment. Let’s devote a few minutes to recognizing potential changes, and what they mean to us as specialists.

The Age of the CFO

It’s the dawning of the age of the CFO. Across the country, chief financial officers are inserting themselves into business decisions – not just the big stuff. New financial realities created by tightening financial policies drive major changes. One executive VP of a major corporation says his signature buying authority has been cut from a half million dollars to ten thousand. New emphasis on detailed financial planning includes the development of value-based decisions. What does this mean for us? In the future, our success is tied to how we help customers understand intrinsic value – in a detailed financial way.

Dollarizing your organization’s value is a critical skill. Product features – bells and whistles – take a back seat to financial impact. We must lead our sales teams in creating financial snapshots of the value built by our solutions. We need to gather financially oriented information from our accounts and incorporate it into our selling process. The customer’s cost of downtime, parts inventory, shop space and inventory costs are critical to sales success. If you don’t know and understand these points, you may find yourself in the supplier soup line. To help, we have created a short list of questions you must know and understand.

1) What is the dollar amount associated with downtime or work stoppage?

2) What is the burdened labor rate for labor?

3) Does the company provide training to its employees?

4) What is the cost of this training?

5) What is the total number of products produced per hour / day / week / etc.?

6) What is the percent of waste / scrap produced by the plant?

7) Is there a dollar amount associated with this scrap / waste?

8) If a reject is produced what else is ruined?

9) What are the costs of energy and other in-house utilities?

10) What payback level is needed to meet company standards?

Get ready for a margin squeeze

Don’t shoot the messenger – this is an unpopular topic. But, we should prepare today for an attack on the lifeblood of distribution. As customers and suppliers jockey for improved profits, the middle man really is caught in the fray. Here’s why. Vendors responded early to the recession by right-sizing their sales force. And, we observed a similar trend in our customers. A recent blog on purchasing.com outlined “layoff survival sickness” – workers who survived downsizing trends find themselves responsible for twice the work.

Soon we face a perfect storm of margin squeeze. As newly rehired supplier salespeople pitch their products to recently readded purchasers. The new folks will instinctively struggle to prove their worth – low-ball quotes will fly like mosquitoes in a Minnesota marsh. The squeeze stands to threaten any upside gains in our industry.

Specialists must play a pivotal role pricing strategy. Specialist-driven products demand proper margin. If you support a technology grouping or product line of highly supported and application-specific products, the value you add justifies a better margin than commodity products your company may also sell.

Don’t expect your customer service or quotations department to understand the difference. To illustrate, allow me to relate the story of Hobbs. Hobbs worked as an inside salesperson at an electrical distributor. Every day he priced dozens of invoices. And he knew a reasonable margin when he saw one, until his company took on a line of cutting edge sensors. It was a one-of-a-kind product with a margin double the norm for his industry. When Hobbs noticed the “outrageously high” margins on the computer, he decided to set the margins back to a “reasonable” level. With a few quick flicks of his index fingers (he was a two-fingered typist), he managed to blow away thousands of well-deserved margin dollars.

If you can’t ensure that your sales team prices your products properly, I suggest you begin working with your management team to establish checks and balances.

Get ready for expansion

“Go west young man,” commanded Horace Greeley. Today, distributors are driving a new kind of expansion. Distributors are planning to expand the product lines they offer existing customers. That means electrical distributors will sell safety products, mill supply houses will pick up electrical products lines and fastener guys will distribute specialty tools. Imagine the pricing confusion this will create. Think about training opportunities. Rest assured, specialists stand to be at the vanguard of the action.

What happens when the specialist possesses a keener understanding of market dynamics than their company’s management team? We have long expounded on the specialist’s role as coach and mentor to their sales team. In the future, you may be called upon to mentor the boss. In preparation, can you chart out these questions?

- Which supplier organizations are the up-and-comers in your technology group?

- Are there natural synergies between suppliers?

- What other non-competing distributors might be willing to share best practices?

Communications between management and specialist grows with the territory.

The skinny supplier sales team

The skinny supplier sales team

Take a moment to consider the supplier sales teams that you work with. Where are they? Across distributor-land, more and more folks are finding their suppliers missing in action. If your key lines had five people supporting a territory in early 2008, today they may have three. The bigger the company, the greater the chances the local sales team was downsized. This impacts specialists.

Do you find yourself responsible for factory quality issues? How about expediting? But the biggest impact may come with training. In years gone by factory reps carried much of the training burden. Guess what? In the post-recession times, you will be the training go-to guy.

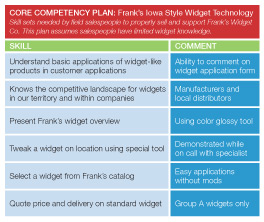

As the economy heats up, you need a plan for training. Introducing new products to old employees and bringing new people up to speed will be your responsibility. I suggest you begin creating some plan for the future. If you haven’t built a core competency plan, see the sample on the left to get you started.

It’s important to note that we have set the minimum standards for our sales team. The competency list should be published and understood by everyone – management, sales and specialist alike. This sets a metric by which each person can be measured. And it builds a plan for focusing your training. Training without a goal is frustrating for both trainer and trainee.

Color outside the lines

Lines, what lines? I believe the lines are blurring. Specialists in the future need to dig for creative tools to push their selling agenda. When the opportunity presents itself, challenge your supply partners for creative tools for driving your business. Everything counts: free demos, sample software, extended payment terms, shared sales resources and training allowances might be part of the discussion. Ask for them to pay your way back to the factory so you can meet with their marketing folks. Talk about extending their marketing plan to your territory. Be creative – the future is far less scary when you take a hand in creating it.

Frank Hurtte of River Heights Consulting has developed a unique training system for distributor specialists. Reach him at (563) 514-1104 or frankehurtte@riverheightsconsulting.com.

This article originally appeared in the Jan./Feb. 2010 edition of Industrial Supply magazine. Copyright 2010, Direct Business Media, LLC.