|

by Kim Phelan

“No, no, no!,” Travis Gavala told his customer. Branch manager at ARG Industrial’s Everett, Washington, location, Gavala said the customer claimed they’d been using the camlocks on air hoses for 20 years.

“Well you’re not using them anymore,” Gavala replied. “I provided them with documentation from the fitting manufacturer and told him we recommend going with this other design for the size and volume that they were using. We didn’t hear anything from them for a while, and then all of a sudden, they were ordering adapters and whip checks and everything of that nature. I was like, ‘You have a potential for serious safety problems,’ and thankfully they listened. They saw we had the knowledge and the documentation, and they made that change.”

It’s not a rare scenario. Misapplication – installing the wrong hose and/or fittings for the job – is one of the top causes of hose-related accidents. Whether by deliberately taking shortcuts or due to lack of knowledge about proper safety protocols, hose mishaps can cause devastating injury, harm to the environment, and even potential litigation nightmares for customers, distributors, and manufacturers.

For these reasons and more, the members of NAHAD – The Association for Hose and Accessories Distribution, have made hose safety a top priority for the last three decades, and the emphasis has only intensified for the last three years. In the fall of 2023, NAHAD launched Hose Safety Awareness Week, which will unfold once again across the U.S. September 7–13. And NAHAD members are stepping up their game, taking attention-getting campaigns to social media to educate customers and remind them that safety is the NAHAD member’s No. 1 priority. The week’s focus on safety awareness also gives distributors a chance to strengthen their safety culture internally among employees who are fabricating hose assemblies and making service calls in the field.

“Whether a distributor participates for one week or throughout the month, the goal is to show their customers what they do all year long so they know how committed these particular distributors and manufacturers are to hose safety,” said NAHAD Executive Vice President Molly Alton Mullins. “And that’s a major reason customers choose to do business with them. The purpose of designating a specific week is to increase the scrutiny of safety during that particular time, but really, this is who we are all the time.”

NAHAD’s emphasis on safety is year-round. Its Hose Safety Institute (HSI) committee has appointed a task force this summer to create a new visual inspection guide, which may be completed early next year. The association has also put more teeth into its Hose Safety Institute (HSI). Last year, the safety committee modified the pathway to HSI membership, requiring 50% of a distributor’s employees to be HSI-certified and regularly updated every three years. Member distributors that are committed to the rigorous training and record-keeping say the certification is a major competitive advantage in the marketplace.

“Certification means a lot,” said Paul Lombardo, Midwest general manager of Singer Industrial companies Allied Rubber, Ray Lewis & Co., and Summers Rubber Co. “When customers ask us questions about our products and services, our common response is, ‘We build and test your hose assemblies to certified standards. We go to market with that and use it as a differentiator in the field. We are NAHAD certified – we follow a set of rules that other vendors may not.”

Scott Bauman, chair of NAHAD’s HSI committee, agrees there is a stature that comes with a distributor’s HSI affiliation. “If you’re an HSI member, it’s really about being able to tell your customers you are part of the top organization in the country for hose safety, and being able to showcase that you are doing everything possible to make safe assemblies they can use and trust.”

EDUCATING THE CUSTOMER

The hazards associated with hoses in all kinds of industries and applications are sobering.

“For example, somebody puts an air hose on an oxygen hose. Nine out of 10 times there’s going to be no problem, but if they grab their dirty hose and stick it on an oxygen line, it’s going to explode,” said Lombardo. “Oxygen explodes when it touches dirt. Everything needs to be very clean. Misapplication of a hose is a huge problem. An employee sees a hose and they just grab it and put it on. They don’t know what they don’t know.”

Another major cause of injury is improper installation or assembly. That means more than compatibility between hose and fittings: End users must be careful not to route a hose where it’s going to be exposed to abrasion that could rub a hole through the hose cover and cause a hose to leak or explode. Failure to inspect and replace old or damaged hoses leads to the kind of negligence that creates risks to workers. In addition, exceeding rated pressure or temperature limits for a hose is another oversight that’s rife with risk.

Workers in any of these scenarios could be exposed to facial injuries, cuts, burns, and even illness resulting from hydraulic fluid or dangerous chemicals penetrating their skin. Secondary to these potential traumas, customer companies have a lot to lose, too, when an injury occurs.

“If they have a lost time accident or an event that could shut a portion of a plant down, it can be earth shaking financially,” said Rob Lyons, co-CEO at TIPCO Technologies.

“It’s our duty to educate, and it’s our duty to warn,” he added. “And we take that incredibly seriously – I think most in our industry do. It’s one of the things that, frankly, keeps me up at night. I want our employees and our customers to all go home with their fingers and toes and eyesight all intact … Safety is a culture. It either exists in your organization or it doesn’t.”

Lyons says his company offers inspections at customer sites as part of their dedication to educating them. “OSHA is very aware of our industry, and the fines for violations can be extremely steep,” he said. “So customers are usually open to safety surveys, where we will come in and, if they allow us, take pictures of safety challenges. Very often we’ll refer to the Hose Safety Institute when we see something that looks unsafe … If the customer can see it and understand it, as opposed to just a Zoom event or reading a document, it’s way more impactful.”

Listening to the customer is critical to ensuring their safety. Distributors agree it’s essential to understand how and where end users plan to install and use a hose assembly.

“You get people who call and want this hose with that fitting, and you could just sell them that, or you could understand what they’re doing and what their application is – and offer them a better solution,” said Tyler Mitchell, branch manager of ARG Industrial in Fairbanks, Alaska. “Yes, we sell hose and fittings, but what drives the value for our customers is that we’re knowledgeable in our field and selling them safe solutions for their problems.

“This isn’t like retail – they’re not here to shop,” he continued. “A lot of them already have issues with an old hose that has failed. We go over their application and what their situation is and help identify what caused it to fail or what the weak links are.”

Lombardo noted that distributors can – and should – play a central role in keeping end users safe. “They are often the last line of defense before a hose assembly is installed in a high-risk environment,” he said. “When done right, they move from being just ‘product sellers’ to becoming trusted risk mitigation partners – distributors who educate proactively, document meticulously, and communicate with the end-user’s work reality in mind. They don’t just sell hoses – they reduce injury, liability, and downtime. And that’s what earns loyalty.”

|

THE BLAME GAME

If a hose-related accident occurs and someone is hurt on the job, the triangle of blame begins, says Lyons. Attorneys can go after the customer company, the distributor, and the manufacturer. But here again, the value of HSI membership and diligence to maintain a daily culture of safety pays off.

“If you’re deposed in a case that involves a hose product … the very first thing that the law community is going to ask you is, ‘What gave that sales person the qualifications to suggest what the customer should use?’” he said. “HSI can be a foundation of training that frankly could help mitigate litigation if you’ve proven that you’ve acted with a duty to educate and duty to warn in the onboarding process of your customer-facing people.”

Lombardo believes hose failure-related injuries are seldom the fault of the distributor. “It’s usually a misapplication or an improper installation. We’ve seen where customers have used our hose as a step and damaged the hose. Or they’re feeding a fluid through it that it’s not intended for.

“At the end of the day, distributors can get swept up into legal cases, but that’s where we go back to the NAHAD rules – if you’re doing your job correctly and applying NAHAD standards, you really don’t have anything to worry about,” he said. “Yes, you might have to go to court, but most of the time the distributor is not held liable.”

Sometimes it’s a case of false identity. Lombardo says he gets occasional calls and emails from customers claiming his company’s hose failed, which used to be upsetting, but not anymore. The distributor now physically lasers the invoice number onto every hose they make, giving traceability to all their products in the field.

“I used to get all bent out of shape and freak out when I’d get those complaints – now the first thing I say is, ‘Hey, send me a picture of the end fitting on the hose.’ I can usually tell by just looking at the hose if we made it or not by the way it’s assembled and the brand of the hose. Traceability has become a big thing in the industrial distribution because of the threat of litigation.”

KEEPING END USERS SAFE

Sources say the distributor is always “on” when it comes to educating end users.

“We’re always out there talking about safety as we interact with the customers, explaining what to use, what not to use, what is and isn’t compatible with different types of metals, oils, or gasses,” said Gavala at ARG Industrial. “You want to give customers a good base understanding. But you need to find and talk to the right person in the organization who wants to hear about safety – like the safety officer, shop foreman, or a manager who’s in charge of OSHA incident reports. They’re the ones who are listening.”

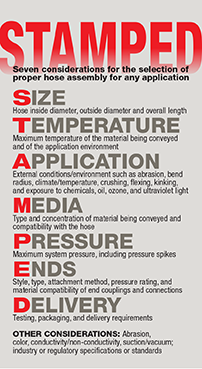

Resources to offer customers are plentiful. Sharing the industry’s “STAMPED” checklist is a good place to start. NAHAD’s HSI is another resource, as well as manufacturer manuals and videos.

|

Some distributors also offer training in-house and at customer sites. And ARG Industrial is taking hose education to an innovative digital level with a web-based hose builder tool for customers. ARG, a stakeholder in the software’s creator, IntelliBuild, rolled out the tool in 2024, and it continues to evolve.

“The hydraulic portion is up and we’re in the middle of building out the database for the industrial side now,” said Mitchell. “It will take away the potential for mismatching fittings on hoses. If you pick a certain type of hose, you will only see options for the right kind of fittings.”

Watch for more distributor creativity and communication as Hose Safety Awareness Week hits the internet beginning September 7, and visit https://nahad.org/hose-safety-awareness-week/ for details and events.

SAFETY IS A COMMITMENT

At Dixon, safety is more than a priority; it’s a commitment. In support of NAHAD Hose Safety Awareness Week, we’re proud to highlight the products and services we offer to help distributors and end users operate safely, efficiently, and confidently.

Partnering with valued distributors, Dixon offers On-Site Safety Training to help identify potential safety hazards and provide recommendations for corrective action. Hose Coupling Workshops are also conducted throughout the country to enhance understanding of proper hose assembly, application, and inspection, helping to reduce the risk of failure and injury in the field.

|

In addition to training, Dixon offers a comprehensive lineup of OSHA-compliant, safety-focused products. Our King Safety Cables® are the first line of defense, providing a proactive solution to minimize damage when hoses, couplings, or clamps fail. For added protection, safety check valves shut down the air supply if the valve senses an increase in air flow, which prevents a hose from whipping.

Other Dixon products like Venting EZ Boss-Lock were designed with safety in mind. In the event of disconnection under pressure, the venting feature retains the coupling and allows the stored pressure to vent off. Meanwhile, backed by rigorous testing and engineering standards, Dixon’s King Crimp® system provides a consistent and reliable method of attaching fittings to hose.

Advancing hose safety through innovation, education, and support is what Dixon is all about. Join us in observing NAHAD Hose Safety Awareness Week by prioritizing training, choosing The Right Connection®, and reinforcing best practices every day. Remember, safety isn’t optional—it’s essential.

For more information visit dixonvalve.com or call 877.963.4966.

CAPLUGS SAFE-SLEEVE: SUPERIOR HOSE BURST AND PINHOLE LEAK PROTECTION

Caplugs, a leader in the fabrication and distribution of hose safety products, is proud to offer the uniquely designed Safeplast Safe-Sleeve hose sleeve protector. The Safe-Sleeve can be easily installed over hoses of varying sizes, offering reliable protection against hose failures in a variety of industrial environments.

When a hose failure such as a burst or leak occurs, it can leave equipment and workers exposed to dangerous fluids at intense pressures. The Caplugs Safe-Sleeve helps mitigate these risks by safely dissipating fluid out the sides of the hose sleeve.

The Caplugs Safe-Sleeve is uniquely designed with a polyester material and woven with a high yarn count, allowing it to protect against these common hydraulic hose failures. The higher yarn (thread) count of the sleeve also provides exceptional dimensional stability, ensuring reliability under tough conditions.

The hose sleeve features a flame-retardant coating proven to self-extinguish flames in as little as 30 seconds, as well as anti-static/conductive threads that allow for static charge to ground at the ends of the sleeve instead of building up. It is also tested to 400 bar (5,800 PSI) and is MSHA approved (IC-319/2) for mining applications.

|

Furthermore, this hose protection sleeve provides excellent UV, moisture and chemical resistance, especially when compared to nylon alternatives.

Other Advantages of Caplugs Safe-Sleeve:

- Stain resistance (doesn’t leave oily stains)

- Good abrasion resistance when wet

- Anti-abrasion solution for hoses dragged on rough ground like gravel or rocks

- Safe working temperature up to 300° F

- In stock and ready to ship

Available in multiple sizes and widths with custom printing and cut-to-length options, it’s the economical choice for comprehensive hose burst and leak protection. Don’t wait for a costly hose failure to occur. Protect your teams and equipment with Caplugs Safe-Sleeve product, the proven choice for industrial hose protection.

UNIFLEX-HYDRAULIK: ENGINEERED FOR PRECISION. TRUSTED WORLDWIDE.

For over 55 years, UNIFLEX-Hydraulik, headquartered in Karben, Germany, has been a global leader in the design and production of machines for hose assembly, from compact crimpers and cutters for mobile workshops to full-scale automated production systems. Our equipment is built to serve the unique needs of hydraulic hose manufacturers, distributors and service providers with a focus on reliability, performance, and long-term value.

At the core of our technology is our patented grease-free slide bearing system, which eliminates the need for lubrication and significantly reduces maintenance. This not only improves efficiency and cleanliness, especially important in mobile and field service applications, but also reduces energy consumption and operating costs. The result? Cleaner operations, fewer breakdowns, and more uptime where it counts.

UNIFLEX machines are designed in collaboration with industry leaders and field technicians alike, making them exceptionally user-friendly, robust, and accurate. We offer a full range of hose processing solutions including hydraulic crimpers, hose cutting machines, skiving machines, test benches, fume extraction, and more, all engineered to withstand demanding environments and deliver precise, repeatable results.

We are proud to be ISO 9001 certified and maintain a strong global presence with eight subsidiaries and more than 140 employees serving over 20,000 customers worldwide. With our North American headquarters in Schaumburg, IL, we provide local support, training, and fast service to keep your operation running smoothly.

Whether you’re a small service provider or a large OEM, UNIFLEX-Hydraulik offers scalable solutions that grow with your business. And because we are independent of hose and fitting manufacturers, we provide truly unbiased equipment tailored to your specific needs.

Visit www.uniflexusa.com to learn more.

This article originally appeared in the September/October 2025 issue of Industrial Supply magazine. Copyright 2025, Direct Business Media.