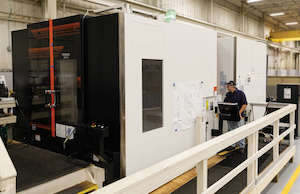

Hyson adds advanced turning machine to Brecksville, Ohio, facility

Hyson, a business of Barnes Group Inc. and provider of nitrogen gas systems for metal forming operations, announced the upgrade of its Brecksville, Ohio, facility with two new machine tools to provide faster and more diverse gas spring solutions.

The new machines are state-of-the-art CNC mill/turns that efficiently produce precision high-quality metal components. With the addition of these multitasking machines, Hyson now has a handful of advanced state-of-the-art turning and milling centers that can produce a wide array of small, medium, large, and extra-large springs and engineered solutions.

The new machines are state-of-the-art CNC mill/turns that efficiently produce precision high-quality metal components. With the addition of these multitasking machines, Hyson now has a handful of advanced state-of-the-art turning and milling centers that can produce a wide array of small, medium, large, and extra-large springs and engineered solutions.

The newest machine tools added to Hyson’s facility can turn a workpiece and apply various operations such as facing, grooving, threading, boring, and milling. They feature high-speed spindles, powerful motors, and an advanced control system. These advanced machines allow for even more diverse manufacturing capabilities.

With a complete range of capabilities, Hyson’s machines can handle a wide range of materials, sizes, and shapes. Automatic tool changers are one of the most beneficial features, holding up to 72 tools each, allowing for quicker and easier setup and changeover—and ultimately increased productivity with less lead time for the customer.

Hyson’s in-house advanced turning and machining centers can produce standard and customized parts in a matter of weeks. Other benefits of these machines include:

- Up to 20% reduction in cycle time.

- Part order-to-delivery in weeks instead of months, saving customers time and money.

- Enhanced productivity by minimizing setup time and reducing waste.

- Improved accuracy by ensuring consistent sizes of the finished part.

- Increased flexibility by allowing for customized specifications and modifications.

- Optimized performance by using optimal cutting parameters and tooling selection.

- Ensured reliability by creating high-quality components with robust construction and minimal maintenance.