How Affordable, Compact Technology is Leveling the Playing Field and Revitalizing Small Businesses

By Nisan Lerea, CEO, WAZER

The United States Chamber of Commerce reports that over 99% of U.S. companies are small businesses. Despite this, large offshore factories dominate manufacturing. Small manufacturers and entrepreneurs, once the bedrock of industry and innovation, are being left behind, pressured by rising material and overseas labor costs, and now squeezed by the digital revolution.

Modern manufacturing often requires large-scale budgets for costly equipment and staff, beyond the reach of most small businesses. The playing field needs leveling, to foster a more diverse and resilient industrial sector that drives economic growth and job opportunities.

A recent study from the Reshoring Institute shows that labor rates are rising in countries once considered inexpensive for manufacturing. When combined with high material costs, plus logistics and quality control expenses, outsourcing production can become less financially attractive for U.S. businesses.

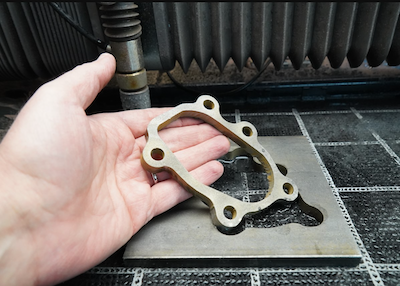

Fortunately, emerging innovations in subtractive manufacturing provide more options to small businesses looking to cut costs while keeping their production in-house. With new small-scale but high-tech waterjet cutting machines, local manufacturers can now control the production process, making products on-demand at efficiencies they could never have before.

This user-friendly and affordable CNC machinery enables new start-up companies to innovate and become self-sufficient and helps bring manufacturing back to local communities and small businesses, while also helping reverse the decades-old decline of local manufacturing.

The benefits of this technology are not just limited to small-scale manufacturers. Design engineers can also take advantage of the affordability and flexibility of compact waterjet cutters, which can produce new product concepts in-house much faster than outsourcing. Waterjet cutting machines can produce parts out of any material, to enable rapid prototyping during the design phase, quickly and accurately producing high-quality functional parts for testing and refinement.

These advancements in subtractive manufacturing technology provide manufacturers and engineers with the freedom to innovate and compete at the same level as large manufacturers. By utilizing these machines, small manufacturers can become more efficient and nimbler, enabling them to produce high-quality products at lower costs. This not only preserves the jobs of local craftsmen but also fuels innovation across the entire industry.

About the Author

Nisan Lerea is the co-founder and CEO of WAZER and an inventor of the world’s first desktop waterjet cutter. A consummate “maker,” Nisan spent many hours in the machine shop during his time at the University of Pennsylvania working on projects including a Formula 1-style race car. He needed to cut sheet metal but only had access to laser cutting, which could only cut soft materials. Nisan set out to solve the problem, inventing the first small-scale waterjet that would become WAZER. While working as a mechanical engineer, Nisan realized that other designers and engineers still faced barriers to waterjet cutting, so he teamed up with former colleague and fellow Penn Engineering student Matt Nowicki to launch WAZER in 2016.