|

by Kim Phelan

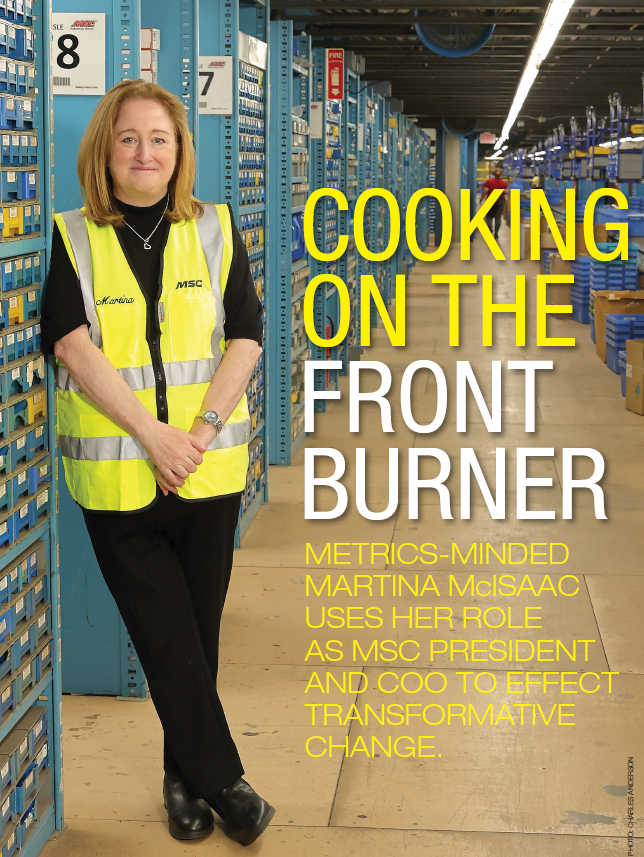

When Martina McIsaac gets fired up for a cause, good things tend to happen. It’s true both in the business life and out-of-office activities of the recently-appointed president of MSC Industrial Supply.

For instance, McIsaac, who is passionate about women’s issues, takes an annual, one-week volunteer trip with her daughter to install smoke-free stoves in the homes of impoverished families in Guatemala. In the span of about 45 minutes, they drill a rooftop hole for a chimney and hook up a stove inside – it’s a lifechanging event for women and girls who are otherwise required to stay home and keep an outdoor fire burning all day. Not only do the stoves introduce a cleaner, healthier environment, but, says McIsaac, they free women to seek job training and work outside the home, and girls are able to attend school.

Spend a little time with McIsaac, and you quickly recognize her fire for MSC produces measured, swift action, as well.

|

| McIsaac, hidden by her cap, and her daughter, Annelies, build a stove for a family in Tecpan, Guatemala. |

In the two years since joining the publicly-traded distributor, she has, in a sense, helped peel off some shingles to drop in new game-changing strategy. A metrics-minded leader, McIsaac is a listener, solver, and doer who’s continually on the floor with employees throughout MSC’s 46 facilities, a practice that fuels her business knowledge and decision-making.

On September 23, 2024, the Six Sigma Blackbelt was promoted to MSC president – only the fifth in its history – just shy of her two-year anniversary with the company, where she began as chief operating officer, a title she still retains. McIsaac left her role as CEO at Hilti in 2022 for the opportunity to join MSC CEO Erik Gershwind in evolving the 84-yearold distributor into its next chapter.

“Erik is an inspiration, and MSC’s origin story is inspirational,” she said. “At different times of its history, the company has really been out in front in terms of innovation. In the ’60s, we were using computers to send people to the moon, and Sid Jacobson, our founder, decided to invest in computerized inventory for the industrial distributor. And then, long before anybody heard of Amazon, we had the service promise of order by eight, get it next day.

“So really, there have been these big moments of pivots for MSC,” she added, “and Erik made one of those pivots when he took MSC into this high-touch segment. A transformation across the whole business is really underway, and I wanted the chance to work with him on that transformation.”

In her first two years, McIsaac’s priority was taking the core pieces of why customers come to a distributor – offer, relationship/responsive support, and timely execution – and applying those value propositions into “four lanes:” (1) metalworking, (2) MRO, (3) consumable parts, and (4) fasteners and other production inputs.

“We now have owners of these four lanes that can develop supplier relationships heterogeneously, and together they create the offer – or ‘set the buffet’ – for the sales team,” she said. “With this change to becoming president, I’m now bringing the technology function and all of the marketing activity around our uncovered, digitally-managed customers under one roof, so we can optimize our process.

“I solve problems through process, looking at the business end to end and designing a structure that has the right hand-offs and at the right time,” she added. “This has been really exciting and important for me, and I think we’re poised for growth.”

|

| Martina McIsaac spends a little time with associates at MSC's Atlanta fulfillment center. |

TURNING UP THE GAS

Just over two years later, with the foundational work of four lanes laid, McIsaac has a new set of top priorities, each aimed at multiplying existing strengths of the company.

First up is culture – harnessing the great commitment and enthusiasm with which team members serve customers and moving that energy into a continuous, longer-term process.

Next, on the business side, she’s placing emphasis on augmenting what she calls MSC’s strongest value proposition, its technical competency.

“MSC has an incredible reputation for technical integrity,” she said. “We can go in to a customer, optimize their process, make the best recommendation for the products they need and how to reduce their energy consumption, speed up their production – all these things that we do are really core to our value proposition.

“Over the last decade, the business has pivoted toward this high-touch approach, and right now, roughly 60% of our business goes through some kind of inventory management solution at a customer,” she continued. “We have specialists in the field that are supporting optimization at customers’ facilities. We actually commit to cost out for our customers and we provided documented savings of over a half billion dollars last year. So we want to keep that momentum going, and that’s one of my big priorities.”

Part of that effort includes reorganizing company resources in order to halve the time in which its teams can get a new customer operational with MSC-installed systems and processes.

“Another priority is that we need to find new avenues of growth, and one of those is our geographic expansion.” McIsaac said. “So we made a couple of acquisitions in Canada. We’re also investing in our business in Mexico, and we’re working together with our biggest customers that are going there.”

She’s also working intentionally to reenergize MSC’s traditional customer base. “MSC grew up as a catalog house and we were known as the place where, if you needed it, we had it,” she said. “With me bringing technology under my roof now, we really want to accelerate some of those web upgrades so that we can regain our core customer.”

Last but not least, McIsaac is turning up the gas on MSC carbon reduction as both a cost-cutting and environment-protecting priority. “We can eliminate the number of split shipments and the number of air shipments,” she said. “All of that puzzle is really fun for me.”

|

| Martina McIsaac and Brian Bello, vice president and interim CIO, collaborate on technology projects that improve productivity for customers. |

DARTS ON THE BOARD

Like many distributors today, MSC is developing and executing its own AI implementation plan and keeps the power of the technology closely tied to customer benefit.

“If you think about what a distributor does, it brings thousands of suppliers together with hundreds of thousands of customers, and so AI is a perfect tool for us for things like product search and selection,” McIsaac said. “That’s how we’re thinking about it. What we hope to do is to provide consultative, data-driven solutions to our customers. We’re doing that through other means today, but we see AI as a big unlock there.”

She added that the company’s Research Technology Group is taking the lead in this area. Coupling its internal analytics capabilities with AI, they’ve seen a surprising value-added service opportunity emerge.

“Believe it or not, one of the things for which customers most rely on us is giving them their own consumption analytics – which is funny, but that’s what they want from us,” McIsaac said. “So we are looking at how we can continue to make good recommendations and help them develop standards, and do that by digital means supported by AI.”

Manufacturing’s difficult business environment certainly made 2024 a ripe time for distributors to throw all available darts – including AI tools – at the board to remain profitable. McIsaac said MSC’s key metals markets, including automotive and heavy truck, softened last year, the exception being aerospace. Interest rates and labor interruptions curtailed investments, and pre-election breath-holding didn’t help matters. Some trepidation remains as industrial distribution steps over the threshold into 2025.

Speaking in late November, McIsaac said, “What we are measuring during this time is how are we taking share in this challenging environment. We have over 25,000 vending machines in service – we grew that installed base by 9% last year, and we grew our in-plant program, so those are the biggest customer wins where we actually put onsite MSC representatives in the customer’s plant. We grew that by 30%.

“But when you look at revenue through those programs, it’s been relatively flat,” she continued. “We think about it like a coiled spring. We still did what we needed to do. We still won the customers and installed the base that will be the springboard for growth once growth comes back. In terms of triggers for what might turn things around, we’re already seeing some green shoots in our OEM business, which probably comes first, because that’s direct production. Everybody had a difficult year, so there are a lot of customers that are extending what their normal end-of-year shutdowns would be, so we expect our December to look seasonally the same as it always does – but we’re hoping we’ll start to see that rebound in January.”

Even before a comeback, MSC is taking action on things it can control. These include: (1) Upgrading its statistical planning to better balance inventory across the network, which will result in the reduction of air freight and split-shipments. (2) Leveraging its purchasing power across its entire business – efficiencies they expect will cut about $15 million in operating expense. (3) Redeployment of its approximately 2,700-strong salesforce – evaluating territory management and customer assignment to ensure resources are being used to achieve optimum outcomes. Without any additional head-count investment, MSC expects to cover about $300 million more customer potential.

“It’s not unlike putting a vending machine in the right place,” McIsaac said. “We want to put people in the right place and cover more of those core customers – that’s a big piece of getting our growth engine going.”

DIFFERENTIATED IN THE MARKET

As a company, MSC Industrial views itself in a unique and interesting position in the marketplace, serving up the large-scale offer of a national, the relationship of a local, and tipping the scale with a strong technical reputation, McIsaac says.

“The customer has a person they’ve trusted for years in their plant with their metalworking support, who now is saying, ‘Hey, let me also help you in this part of your business or that part of your business,” she said. “And because the trust exists, that’s a real differentiator, and we’re able to grow share of wallet very quickly.

“We think that’s the secret sauce, and then together with our suppliers in each of those lanes and having such a big assortment, it becomes a force multiplier for us.”

|

| MSC associates test and validate a vendor install at a customer's location. |

McIsaac points to three levels of investment planning she keeps in plain sight. Level 1: Managing all the things customers care about, such as product choices, on-time delivery, price, and ease-of-use with e-commerce. Level 2: Helping the customer optimize their business through inventory management and identifying areas to save money.

“And at Level 3, we are thinking about the things our customers are not thinking about yet.” McIsaac said, “This includes using our proprietary innovations like MSC MillMax, which is a way for our customers to optimize how their machines run – we are trying to meet customers where they are. They don’t have as much trained labor as they used to. So we look at how to bridge that skills gap for them with technology.”

THE BEST THINGS A LEADER CAN DO

The No. 1 trait McIsaac values most and actively cultivates as a leader is clear, transparent communication.

“Any time I have stubbed my toe in my professional career, it’s been because I pulled back from communicating and under-anticipating how much clarity and transparency people need,” she said. “That’s probably one of the biggest features of the way that I lead.”

At MSC Industrial, she has launched a monthly video session called Top of Mind, during which she speaks directly to the whole company about current hot topics, taking questions, and engaging about a fourth of the company’s 7,400 employees on any given call.

“Culturally, it’s been a really good fit, because that’s the way I like to lead – as transparently as I can and with high communication.”

McIsaac also leans into listening for good leadership. “My very first general manager job was with a business involved in polyolefin film extrusion,” she explained. “Well, I’m not a polymer chemist, and I’m not an engineer. I had never run a heavy manufacturing plant, and we had a very big operational challenge. It was the greatest gift anybody could have given me, because I didn’t have a single answer. None. So I had to listen to my team, I had to ask good questions, listen to experienced people, and then learn to filter.

“Learning to listen really young shaped the way that I make decisions today.”

This article originally appeared in the January/February 2025 issue of Industrial Supply magazine. Copyright 2025, Direct Business Media.