Specialized Service

This New Jersey business has survived for seven decades and counting by reinventing itself to meet changing customer needs

by Rich Vurva

|

| Flexline’s staff averages 20 years of service. Employees include (left to right) Jon Sobral, Brandon Ashford, Phil Iwaniszy, Charity Randall, Lori Battaglia, Jeff Scheininger, Dan Scheininger, Mike Pickerin, Evelio Hernandez, Paul Matias, Sergio Hernandez and Mo Abdullahi. |

Many distribution companies have reinvented themselves over the years in response to marketplace changes. Flexline, a hose and accessories specialist based in Kenilworth, New Jersey, is a prime example.

Harold Scheininger started U.S. Brass & Copper in 1950, selling brass fittings and copper tubing from the trunk of his car. Including “U.S.” in the name lent the business a certain cachet but his primary focus at the time was selling to the trucking industry in the New Jersey area. The post-World War II economy was booming, President Eisenhower championed the birth of the interstate highway system, and the state had become a major transportation hub.

When truck manufacturers began replacing rigid tubing with hoses, Scheininger shifted the focus from brass and copper to flexible hoses. That opened the door to serving other manufacturing customers in the seven county area that needed hoses and couplings. By then, the business was operating out of an industrial neighborhood in Linden, New Jersey, selling MRO supplies to manufacturers that included General Motors, Phillips 66, Texaco, Gordon’s Gin, GAF and others.

In the 1970s, spiraling inflation and major spikes in oil prices took their toll on local industry. By the 1980s, when Scheininger’s son Jeff took over the company, the business climate in New Jersey underwent a sea change. An increase in environmental regulations, which are among the strictest in the nation, and rising taxes—the Tax Foundation ranks the state as the lowest-ranked business tax climate in the U.S.—resulted in many manufacturers moving out of New Jersey.

“The old industrial street where we were located went from a daytime work population of almost 70,000 workers to a work population in the low thousands,” recalls Jeff Scheininger.

“The old industrial street where we were located went from a daytime work population of almost 70,000 workers to a work population in the low thousands,” recalls Jeff Scheininger.

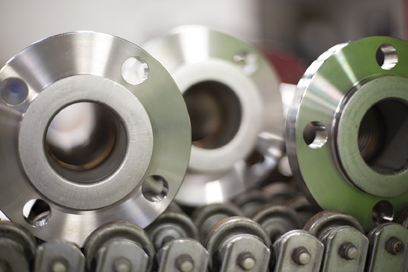

The deindustrialization required the company to shift its focus from serving local factories to providing solutions to a broader geographic area. That change necessitated expertise in more technical products. Today, the company specializes in highly engineered hose assemblies, with an emphasis on stainless steel metal, PTFE, silicones and high purity products.

“We went from a company that was selling in a few counties to a company that’s selling in 40 states and 20 countries,” says Scheininger. “As we became more and more technical, our products became more interesting to a broader geographic reach.”

Customer segments include pharmaceutical, aerospace, food, light and heavy manufacturing, and distribution.

“Our assemblies are used in applications where failure can be catastrophic. This informs our processes and our work quality,” he says.

While Scheininger recognizes that there is a shift toward making B2B purchases online, he believes that specializing in technical applications inoculates the company to some degree from online competition. He estimates that two-thirds of his time each day is spent on engineering solutions for customers, who might not know how to select the correct hose size, type, temperature and pressure ratings for their application and need assistance.

“There’s a big difference between stuff you want and stuff you have to have. The stuff you want, the mall is filled with it, Amazon is filled with it. But the stuff you have to have, people tend to make sure that that’s being built by a specialist,” he says.

Meeting customer standards The focus on highly engineered specialty hose assemblies requires a strict adherence to quality. Many customers insist that their suppliers sign non-disclosure agreements and meet demanding performance standards. Certifications held by Flexline are a veritable alphabet soup of qualifications that include ISO 9001:2015, FDA 3-A, AS9100D, USP Class VI, ASME Section IX weld certifications, Nadcap certifications and more.

The focus on highly engineered specialty hose assemblies requires a strict adherence to quality. Many customers insist that their suppliers sign non-disclosure agreements and meet demanding performance standards. Certifications held by Flexline are a veritable alphabet soup of qualifications that include ISO 9001:2015, FDA 3-A, AS9100D, USP Class VI, ASME Section IX weld certifications, Nadcap certifications and more.

Scheininger says his technically expert field engineering staff is supported by an equally gifted inside staff. “This enables Flexline to recommend the right solution to a customer’s problem every time. We engineer solutions. The customer gets not just a functional assembly, but the absolute right assembly for their application,” he says.

|

CERTIFICATIONS AS9100D, released by the Society of Automotive Engineers and the European Association of Aerospace Industries, is a widely adopted and standardized quality management system for the aerospace industry. IS0 9001:2015 specifies requirements for a quality management system intended for application to any organization. 3-A Sanitary Standard defines requirements for sanitary (hygienic) equipment intended for processing milk, milk products, foods, food ingredients, beverages or other edible materials. USP Class VI refers to one of the six designations for plastics from the United States Pharmacopeia Convention. ASME Section IX specifies the requirements for the qualification of welders. Nadcap (formerly NADCAP, the National Aerospace and Defense Contractors Accreditation Program) is a global cooperative accreditation program for aerospace engineering, defense and related industries. Administered by the Performance Review Institute, Nadcap provides independent certification of manufacturing processes for the industry. |

The staff averages 20 years of service and more than half of the 20 employees have been with Flexline for more than 30 years.

Flexline emphasizes on-the-job training and also supports employees with offsite educational opportunities. Training comes from vendors and from NAHAD – The Association for Hose and Accessories Distribution, and other sources.

“The Hose Safety Institute is an extremely valuable part of NAHAD’s important functions, and over the last year has made great strides as it moves to an online resource,” says Scheininger, who currently serves as NAHAD’s first vice president.

Flexline is also a member of IDCO, the North American co-op of independent hose distributors, and credits IDCO for helping Flexline to compete in new markets.

Scheininger is also active in the New Jersey Chamber of Commerce and serves on its board of directors. When he was chairman of the NJCC in 2011, Scheininger was just the second small business person to hold that position in the 100 year history of the chamber, following in the footsteps of Thomas Edison.

His chamber involvement has provided opportunities to get to know business executives from a wide variety of industries and learn about the challenges that those companies face.

“I don’t know a single small business owner who isn’t working harder and running faster today than he ever has in his entire career. It has become a real challenge in this day and age because your competitive challenges come from so many different places,” he says.

One challenge that many businesses face, but especially small companies, is to develop and continually update the technological infrastructure to meet the next generation’s expectations about how they want to buy.

One challenge that many businesses face, but especially small companies, is to develop and continually update the technological infrastructure to meet the next generation’s expectations about how they want to buy.

“Another challenge is to find the right people interested in our kind of work,” he says. “We probably have a less difficult time attracting employees than other companies in the hose industry because we hire more technical people, but we still have to compete with other companies in New Jersey for a pool of expensive and well-trained people.”

Membership in trade associations like NAHAD helps companies like Flexline gain access to resources to help them find solutions to the challenges they face.

“NAHAD’s professional staff and its board of directors need to provide programs and value to organizations that run the gamut from enormous public organizations to single location corporations,” Scheininger says.

Scheininger believes that charting success in today’s business landscape is more challenging than ever.

“Running a business today requires business owners to be expert at an incomprehensible number of tasks, government regulations, employee issues and technological advancements. It is not for the faint of heart,” he says.

The companies that survive will be the ones that can continue to reinvent themselves to meet the new realities of doing business.

This article originally appeared in the March/April 2020 issue of Industrial Supply magazine. Copyright 2020, Direct Business Media.