Safe and Sound & Movin' All Around

TODAY’S AGV AND AMR ROBOTS ARE BUILT WITH PROTECTIVE AND PRODUCTIVE FEATURES

By Kim Phelan

It’s funny how people inside an industrial distribution business will look at a prospective new capital expenditure differently depending on their particular role with the company. Everyone’s got a different lens.

In the case of AGVs/AMRs (automated guided vehicles and autonomous mobile robots)

|

| To ensure maximum flexibility, E80 says it has been improving and standardizing its SM.I.LE80 software platform. The software controls the complete automation of a production plant or distribution center, from inbound receipt of ingredients and packaging material to automatic trailer loading of finished goods. It allows the effective management of the processes and the systems’ continued improvements over time to meet each customer’s unique and evolving needs. In addition, during the life-cycle of its systems, E80’s customer service guarantees the durability of its solutions, enabling predictive maintenance. |

moving about inside the industrial distributor’s production area and warehouse, if you’re the CFO or finance director, your brow is furrowed over crunching the dollar numbers. If you’re the HR manager, you’re glad some physical burdens will be lifted from your people. If you’re the production manager, you’re excited about the productivity potential.

But if you’re the safety manager (or the one who’s wearing the safety and liability hat) you’ve probably got just one thing on your mind: How can I be sure that nifty robot moving unmanned near our workforce isn’t going to hit somebody?

ANSI/ITSDF (The American National Standards Institute and the Industrial Truck Standards Development Foundation) have made some pretty line-in-the sand assertions, and ANSI/ITSDF B56.5-2019 4.3.2 leaves no room for misinterpretation: “Should an object suddenly appear in the path of the vehicle between the leading edge of the sensing field and the vehicle (i.e. an object falling from overhead or a pedestrian stepping into the path of a vehicle at the last instant), the vehicle shall initiate braking in accordance with a brake system but may not be expected to stop in time to prevent contact with object. In addition, ANSI/ITSDF B56.5-2019 gives clear definitions about guidepaths, maximum vehicle speed, and restricted areas for personnel.

Meanwhile, ISO 3691-4:2020, Part 4, addresses driverless industrial trucks and their systems, providing guidance about operating zones, significant hazards, hazardous situations, or hazardous events during all phases of the life of the truck (ISO 12100:2010, 5.4).

|

| Responding to the need for flexible and adaptable robots that can handle a wide range of tasks and work alongside human workers, Jungheinrich has had its automated stacker and tugger in the North American field for several years, with positive results. In 2021, they refreshed the EKS 215a automated stacker, and in 2022, they introduced the ERE 225a Horizontal Transport for automated floor-to-floor moves. This year, Jungheinrich says it will launch the EKX 516a Automated High-Rack Stacker to handle very-narrow-aisle high-density storage applications. Jungheinrich AG also introduced the Arculus AMR at LogiMat in Europe last year and plans to add it to its North American automation portfolio in the near future. |

Unmanned, autonomous mobile robots are still relatively new, and so are the regulations and guidelines about them – but it’s obvious that standards boards are very concerned about safety wherever the machines are employed.

So are the makers of AGVs/AMRs, who have a lot riding on the adoption of their time-and task-saving machines.

What Makes Them Safe?

Early this year, for example, Rocla, an AGV Brand for Logisnext, will update its entire product line to be compliant with the new ISO 3691-4:2020 safety standard, according to Senior Manager, Sales AGV, Brian Markison. Additionally, the company is adding functionality to work with the inconsistency of pallet placement by manual operators so as not to disrupt the automated portion of the material handling process. Meanwhile, at Stow Group, its robots, fully equipped for autonomous navigation, offer a level of safety far superior to human handling, according to Brian Keiger, business development & marketing

director, robotics. “All of our solution sets follow the related ANSI/ISO specifications and requirements.”

Dan Voris, business development representative, MCJ Supply Chain Solutions LLC (a subsidiary of Jungheinrich and Mitsubishi Logisnext Americas) says companies including Jungheinrich are equipping AGVs and AMRs with a wide range of sensors including cameras, lidar, ultrasound and infrared to improve navigation, obstacle detection and mapping capabilities. Its robots are equipped with safety features such as emergency stop buttons and 3D sensors to detect the presence of human workers and help to prevent accidents. Its products are also being equipped with wireless communication technologies such as Wi-Fi, Bluetooth and cellular networks to improve connectivity and allow for remote monitoring and control.

|

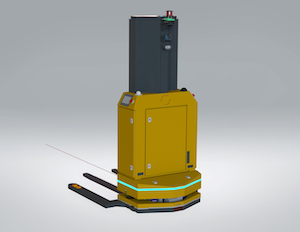

| Safety is an important aspect of Oceaneering’s business, said Patrick Bruijn. Forklift drivers cannot oversee large loads if carried on their vehicles. The company’s autonomous forklift vehicles solve these issues with important safety features. Sometimes forklift drivers are forced to work in uncomfortable ways (driving backwards), which results in physical discomfort and resource failure. Autonomous forklift vehicles such as the MaxMover CB D 2000 can resolve these challenges. |

At E80, engineers have installed new safety equipment and vision systems to make its AGVs more efficient and safer, according to executive vice president of sales

Andrea Pongolini. The use of advanced sensors to detect obstacles allows the company’s solutions to be highly safe and ensure performance, he added.

Sensing Your Presence

While sensors do the detecting of obstacles, including

humans, it’s the AGV programming that determines whether the vehicle should move around the obstacle (obstacle avoidance) or stop until the path is cleared. Such features are fundamental and required by many regional regulations, according to Rob Britt, sales engineer at Kivnon.

While sensors help prevent collisions, they can also provide safety in determining if a load is stable or detect errors within the process in which the AGV is operating, Britt added.

“An incorrectly positioned load presents risks” Britt said. “If not stable, an AGV may fall, causing injury to people nearby or damaging the goods. In extreme circumstances, it may even cause a vehicle to topple. By placing sensors on the AGV forks or lifting area,

information about whether a load is on the vehicle and if it is well positioned can be collected.”

Keiger asserts that safety is always at the forefront of Stow solutions. He said the Atlas 2D solution integrates docking stations and cradles in which the robot shuttle can engage and be lowered to a safe position. Further, he added, mobile tearplates allow for maintenance personnel to safely walk in the storage lanes, and recovery carts make it easy to safely pull shuttles out for maintenance. With Stow’s e.scala solution, there are no moving parts outside the mobile bot that travels up and down the ramps. This allows for little to no maintenance and makes it easy and safe to access, Keiger said.

|

| Kivnon’s Rob Britt says the company ensures its customers stay ahead of the technological curve, and they are able to customize their AGVs to meet their needs. For example, its AGV/AMR forklift K55 pallet stacker is the perfect solution for automating the transport of palletized medium loads at heights. It is designed to adapt to any open bottom or euro-pallet storage application, reception and dispatch of goods, and internal material transport. In addition, this stacker allows proper optimization of the storage space and improves process efficiency. |

“Each of our AMRs have two 3D cameras (front and back), which allow a three-dimensional perception with a wide viewing angle and volumetric detection of objects even at long distances,” Keiger continued. “Perceiving the environment, the safety lidars complement each other perfectly and play an essential role in the 360-degree object detection of the vehicle. Intangible technology developed in-house certifies a secure cohabitation between AMR and operators, whatever the frame being transported. The faster the robot moves in one direction, the more the area stretches. Likewise, the area changes shape depending on the type of support being transported. In any case, if the slightest obstacle enters the robot area, then its emergency stop is instantly triggered.”

Can a robot make decisions to keep its human coworkers safe? Patrick Bruijn, business development director, Oceaneering Mobile Robotics, would say that’s the whole point of its new Supervisory Software platform. It incorporates AI, cloud, IIoT, machine learning, and big data technologies to present a streamlined view of data from mobile robots and other sources to enable better decision-making in industrial environments. “This platform not only considers obstacle avoidance and optimized vehicle utilization, it also offers condition-based maintenance features, which ensures minimum vehicle downtime and reduced maintenance cost,” he said.

Manufacturers realize that safety and performance aren’t an either-or option – and they’re all competing hard to bring the best of both to the industrial distribution environment. For example, Vanderlande’s GtP 2.0 is inherently designed to increase productivity and improve safety as a true goods-to-picker solution, according to Jake Heldenberg, head of solution design, warehousing, North America. Its integrated workstation with a robotic picking arm reduces repetitive manual movements that can make humans prone to injuries and picks at a consistent rate.

Combined with ADAPTO, which eliminates the walking that traditionally took up to 70% of pickers’ time in manually operated warehouses, these solutions dramatically improve productivity, Heldenberg added. Additionally, he says GtP 2.0 was built with a number of ergonomic features including optional height-adjustable platforms, ergonomic mats and an easy-to-use touchscreen interface, enabling users to maintain great working conditions for sustained periods.

Flexibility Matters

Industrial distributors may have common characteristics, but each company and each

|

| Rocla is working through a multi-phase project to incorporate standard forklifts and other AGV/AMR work with its control system to provide the ultimate automation of connecting standard forklifts with AGV/AMR operations. Check out their LinkedIn post for more information: PEAMS – unique collaboration in action | Rocla AGV (rocla-agv.com) |

facility is unquestionably unique in layout and processes – cookie-cutter functionality won’t cut it if more industry adoption is to take place. Flexible solutions to meet customers’ specific applications are paramount, according to Voris. And, he adds, the market needs more flexible and adaptable robots that can handle a wider range of tasks and work alongside human workers.

But what does AGV/AMR flexibility look like? Keiger at Stow says his company’s solutions are easy to scale both from a footprint and capacity perspective as well as throughput standpoint. That’s due to the modular racking and infrastructure design coupled with independently moving shuttles. In addition, the Stow’s AMRs are fully autonomous, navigating without any infrastructure while acclimating to their environment.

“This feature allows the system to systematically be scaled up as needed simply by adding additional bots,” Keiger said. “As always, our solutions are designed and manufactured in-house, thus allowing Stow to control the entire process and ensure the customer that each component is reliable and robust for their application.

Chinese manufacturer Hwachang Intralogistics Technology Co. Ltd., has been dedicatedto shuttle robot product development since 2003, and therefore brings rich, accumulated knowledge to provide reliable, flexible and high performance shuttle systems to meet industrial needs. General Manager Sky Chen says flexibility is a key factor of modern manufacturing. His company’s products are scalable and variable-sized storage units, multiple power supply modes, and optimized integration ofdifferent product series. Hwachang has rolled out two-way shuttles, four-way shuttles, pallet shuttles, carton shuttles, changing-level shuttles, and low-temperature shuttles to meet a wide range of market demands.

|

| To meet the market demand, Hwachang Intralogistics has established a new shuttle AS/RS with variable-size hybrid storage system to improve the storage density and suit for different size boxes and cartons. In the meantime, they have also introduced a faster autonomous shuttle system with high speed to achieve max 2,500 boxes per hour per aisle throughput. |

Two other attributes factor into Hwachang products:

1. Reliability, which Chen says is the top priority in

industrial supply chain automation. “That is to ensure the entire production process continuously runs

without interruption,” he said. Hwachang’s MMBF (Mean Moves Between Failure) offers as much as 200,000 cycles.

2. High performance, without which distributors may not be able to meet their high throughput production cycles. Chen said their products achieve high shuttle throughput of 2,000–2,500 storage and retrieval per hour from a single aisle.

Let’s Talk Trends

Many business and cultural and workplace trends are driving product development in the industrial Robotics/AGV/AMR market.

First is the need for integration. Heldenberg says these systems cannot operate in silos

|

| Distributors must achieve throughput levels inconceivable just a few years ago, while also navigating an incredibly tight labor market and addressing the need for increased storage density, said Jake Heldenberg at Vanderlande. In light of those challenges, the company has made significant investments and advancements to its FASTPICK order fulfillment system. This solution integrates ADAPTO, a roaming shuttle automated storage and retrieval system, along with the Goods-to-Picker 2.0 (GtP 2.0) modular workstation, which has newly added true goods-to-robot capabilities through Vanderlande’s partnership with RightHand Robotics. In testing with some well-known brands, the system is picking 600 totes with only one intervention per hour, said Heldenberg, and he expects that speed to only increase. |

but must be integrated and able to “talk” with one another, and that requires advanced and increasingly intelligent software. While software typically does not receive as much attention as robots and automation hardware, he said, it plays a crucial role and is arguably the foundation for most of the exciting industry advancements. Voirs concurs: He sees a major trend toward integrating robots into existing systems and infrastructures, such as cloud-based services; manufacturing is also mindful of the demand for flexibility to tie into customers’ pre-existing management software.

Pongolini at E80 says that as his company undertakes larger and more complex projects, customers are starting to envision automation as more than going from

A to B – but for end-to-end solutions. With these projects, he says, the software becomes even more important than the hardware. The automated systems need to be flexible, integrated and digitally connected.

“The Internet of Things (IoT) is becoming a critical component of any integrated and automated system. All of our customers want to collect as much data as possible from their systems. This data is critical to managing and maintaining their systems, but customers primarily want to use it to gather strategic business information.”

Other trends affecting product development decisions, according to Bruijn at Oceaneering, include the diminishing size of the workforce, the push for CO2 reduction through electrification of operations, as well as the driving force of high demand for consumer goods, which means increased uptime is more important than ever.

AI adoption, which has more than doubled since 2017, according to Chen, is an 800-pound gorilla of a trend no one can deny. Its growth is sending traditional industry into rapid digital transformation, Chen said, which makes the production cycle more autonomous and efficient. During this transformation, supply chain automation plays an important role to ensure accurate and efficient parts supply to the manufacturing operation. Compared with manual operation, Shuttle Robots/AGV/AMR are more space-saving, more efficient and more precise in distribution automation – in fact, these machines are revolutionizing the traditional industrial system design, he said.

|

| With simplicity in mind, the Stow e.scala solution, conveyors, lifts, and sequencers become a thing of the past. Their e.scala robots move in all three dimensions via a ramp system. The special feature of e.scala lies in the simple scalability of the system, in capacity and performance, high robustness, reliability and uptime performance as well as extraordinary flexibility for a wide variety of applications. In addition, Stow is responding to market demands for optimal use of storage space – its Atlas 2D Automated Pallet Shuttle solution increases productivity. This solution is flexible and scalable: Stow can add shuttles to the system as needs evolve. The 2D shuttle fits into complex industrial projects, and the layout can be adopted to any shape of the warehouse. |

What other trends are bearing down on the development of AGVs and AMRs? According to Keiger at Stow, North American companies are looking to invest in solution sets for “average demand” (80%) and not necessarily “peak demand” (20%). Because of the

constantly changing demand by the consumer, these solution sets need to be flexible and scalable.

He says some of the biggest drivers or trends influencing automation include:

- Supply chain disruption – the finished goods process including storage, picking, order preparation, and shipping are challenged.

- Tracking and traceability – requirements for product tracking continue to increase with industry standards and regulations.

- Rising fuel and freight costs affecting the entire chain.

This article originally appeared in the March/April 2023 issue of Industrial Supply magazine. Copyright 2023, Direct Business Media.