Driving Growth and Profitability

by Cara DeGraff

When a distributor is asked how they differentiate between profitability and operating at a loss, they often list issues like inventory, sales, low costs and optimized prices, to name a few. However, one of the most important considerations is the amount of vendor recovery they receive. Profits aren’t made on the direct customer sale. Profits are made after the sale—with the money they get from special price claims, rebates, volume incentives and marketing funds. This was the case when I worked for a distributor years ago, and it has become mission critical now that the supply chain is tight, and sales are down.

Realizing the correct pricing and negotiating the best baseline costs is essential. Loading costs, suggested list prices and discounts needs to be quick and easy. For example, correctly managed with the right software, managing price loads can go from days to minutes. Pricing becomes a science instead of an art once you have a system that tells you the optimal list price. That’s not to say there isn’t nuance to picking the right price and that it should be taken out of sales control. But salespeople need defined guardrails, so they have more autonomy with the proper controls in place. The result is a win-win situation for everyone.

Getting large volumes still means negotiating special prices to acquire targeted business in competitive situations. A formal system is advantageous to managing all the data you’ve captured, the back and forth on the price that will secure the deal, and with the bids if it is a formal process. Even more imperative is the act of recording these sales and collecting on the price deviation in a timely fashion. These key back-up details will support these claims and hasten the process so you can maximize the money owed to you. With the right software in place, one distributor was able to manage more than 9,000 vendor contracts and process more than $2.6 million in chargebacks each month.

Getting large volumes still means negotiating special prices to acquire targeted business in competitive situations. A formal system is advantageous to managing all the data you’ve captured, the back and forth on the price that will secure the deal, and with the bids if it is a formal process. Even more imperative is the act of recording these sales and collecting on the price deviation in a timely fashion. These key back-up details will support these claims and hasten the process so you can maximize the money owed to you. With the right software in place, one distributor was able to manage more than 9,000 vendor contracts and process more than $2.6 million in chargebacks each month.

Managing the supply chain and sharing information with suppliers gives the distributor a strategic advantage. In this world, the partner with the most information wins. Sales details, selling prices and forecast insights improves communication and gives the supplier the vital details to help them be proactive. Many suppliers pay for this information, whether directly or indirectly. Purchasing incentives or rebates were initially created to lower prices after the fact, but savvy suppliers have recognized there is a superlative way to gain invaluable information. Changing an incentive from purchase-based to sales-based motivates the distributor to not overstock and gives the supplier sales data.

All of this complexity in different rebates (sales, purchases, growth volumes based on quantity, dollars, or weight, attainment based on one set of criteria and payouts on another, retroactive back to the start) requires having a system to store and calculate them, especially one that supports a vast amount of flexibility. A tool is even more important when calculating netting rules for returns, tax, freight, deviations and other rebates. As I think back to the days when I calculated these with countless system data extracts and complex Excel files, I have to wonder how we ever calculated anything accurately. As an example, with the right software in place, one distributor is now able to process $78 million in annual rebate collections. Relying solely on Excel, that would have been an impossibility.

In my current role, I have seen marketing development funds (MDFs) routinely overlooked as viable vendor money. While these typically aren’t taken off the bottom line, they will help improve top-line profitability. When used correctly, they will increase sales. Maximizing this spend and not leaving any money on the table requires careful tracking and proper claiming.

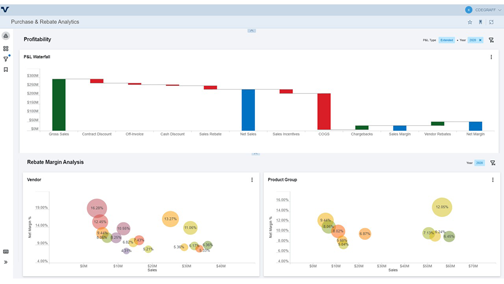

The ideas I have shared so far are tactical in nature. I used to wish for a system that managed these processes and gave me access to the data and analytical tools that are available now. I would spend hours with Excel files doing lookups and pivot tables. Now, the ability to do ad hoc and “what-if reporting” natively, within the applications, allows distributors to make fact-based decisions. Questions such as “Does making a large volume purchase to get extra rebates make sense?” or, “Will a price drop to increase volume be offset by more rebates?” are answered before they are even asked. Today, it’s standard to get alerts and notifications when you are close to the next tier, or your claims haven’t been paid in a timely fashion. Opportunity costs are presented that empower distributors to take the right path. You’ve got to find a way to do the following:

- See the numbers – Get the whole truth, from an aggregate view of your vendor programs to the latest customer pricing.

- See what really works – Get strategic insights from a professional services team with a broader global perspective across a wide range of industries.

- See what to do next – Get the analysis and forecasting you need to know how much to charge, which vendor incentives to utilize, which promotions to run next and what will have the biggest impact on the bottom line.

Having visibility into true customer and product profitability in real time—instead of waiting until a quarter is over and it’s too late to react—changes the game. Taking supplier program gross-to-net calculations into account aids in real-time course corrections and validates whether the right vendor is really the prime vendor. Visibility also confirms your best customers and ensures that they are getting the best prices and rebates.

With so many programs across so many partner relationships, it’s impossible to see where all your money is coming from and where it’s going, let alone how much difference it’s actually making to your relationships and your revenue. So, how can you make sure it all adds up? The only way to do so is by exploiting a robust software solution that helps you take control of your mission-critical processes—ensuring every dollar spent or earned is really driving growth, and not just additional costs.

Cara DeGraff is vice president of product management at Vistex. With high volumes and thin margins, distributors rely on price optimization and cost recovery programs for profitability and income. Vistex supports distributors with software and services to better manage vendor rebates, chargebacks, deals and offers, co-op and market development funds (MDF), price protection programs and trade promotions. With enhanced alignment to business processes, distributors improve margins, guard against losses and leakages, gain visibility into price setting and true costs, incent customers and collect from vendor programs. For more information, visit www.vistex.com.

Cara DeGraff is vice president of product management at Vistex. With high volumes and thin margins, distributors rely on price optimization and cost recovery programs for profitability and income. Vistex supports distributors with software and services to better manage vendor rebates, chargebacks, deals and offers, co-op and market development funds (MDF), price protection programs and trade promotions. With enhanced alignment to business processes, distributors improve margins, guard against losses and leakages, gain visibility into price setting and true costs, incent customers and collect from vendor programs. For more information, visit www.vistex.com.

This article originally appeared in the Nov./Dec. 2020 issue of Industrial Supply magazine. Copyright 2020, Direct Business Media.