Finders Keepers

|

Kurz Industrial Solutions president Brian Nowak equips the business to enter new markets and expand its locations.

There’s a playful old church adage for bachelors looking for a wife: “Pray, but keep one eye open.” It’s possible Brian Nowak applies the idea to his motion control/power distribution business, Kurz Industrial Solutions, headquartered in Neenah, Wisconsin. Nowak, who says he prioritizes daily faith habits of prayer and the study of scripture, is a savvy scout for new avenues of business opportunity. Since he became president and CEO of the family-owned business in 2016, the company has increased its industrial locations from two to four, grown its number of employees from 50 to 95, launched a new automation division, expanded its wind division, and pioneered into new customer markets in the Midwest.

|

The 2024 president of the Power Transmission Distributors Association (PTDA), Nowak is currently and actively pursuing additional growth through acquisition. Emphasizing continuous improvement and growth for himself, his employees, and the company, he’s also living proof that the more you learn about customers and prospects, the more opportunity you uncover and seize.

The apple didn’t fall far from the tree – prior to buying the 106-year-old company with two partners, his father, Rick Nowak, was similarly opportunistic when he was sales manager in the 1970s. Since its beginning, Kurz had operated as an electric motor and mechanical repair business for 70 years, but when customers brought damaged motors to the shop that couldn’t be restored, the senior Nowak recognized they’d better get into the distribution business pronto and helped the company make the shift.

About 20 years later, circa 1996, Brian Nowak joined the company, a newly minted marketing/management/ human resources graduate of University of Wisconsin – Madison. Having made his start in sales, Nowak has more recently led the company into previously unchartered markets of sand and aggregates, power generation and wastewater.

|

“In the northwestern part of Wisconsin, we saw the sand industry really starting to explode,” Nowak said. “Sand in this region is unique in the world and is helpful in fracking. You have to have a certain composite, and in that area, it’s abundant – so a lot of sand companies were developing, and we jumped on that bandwagon. It wasn’t that we had to introduce new products for it – our existing product lines and associated services were a perfect fit. As you can imagine, fracking can go up and down depending on oil prices and related conditions, but despite the ups and downs, it’s been a nice industry for us to be in.”

EYES WIDE OPEN

Keeping an eye open for new markets in which to introduce their products and services is a basic rule in Nowak’s playbook; the key is learning about relevant applications and then reaching out to customers they have not historically called on.

“This has generated nice growth with food processing companies, conveyor companies, foundries, and paper mills for a long time,” he said, “but so do the new industries like sand, as well as other industries we’ve put more focus on – for example, this last year, we’ve had more of a focus on wastewater plants. And we started to sell to contractors more, which is something we hadn’t been doing as much in the past.”

|

Because Nowak is on the lookout for prospective companies to acquire, he says his research and meetings with various Midwestern companies has yielded an education beyond P&L statements. Talks with business owners in different states have revealed insights about industries Kurz can position itself to enter. “It opens up your eyes to what is out there and how our current portfolio of products and services fits right into those applications in a lot of cases.”

UNIQUE VALUE PROPOSITION

Being unique in a geographic marketplace is not an easy feat today, but Nowak feels his company distinguishes itself in key ways. Foremost among them is the service side of the business where trust, technology adoption, and technical aptitude create competitive advantage.

“Our repair business is critically important to our business overall,” he said. “The ability to service what we sell is so important to our end-user clients [that use Kurz’s products in their manufacturing processes] and with OEMs [that put the distributor’s products into their own manufactured goods]. We add value by offering the ability to modify or customize the products to meet their unique needs. In many instances, our repair shop drives distribution business and vice versa as clients seek more of a one-stop shop. Although gaining business always involves building trust, doing so is highlighted even more when it comes to a repair business, which is not as commoditized as a product sale.”

Repair know-how may be rare but it’s not entirely unique, he acknowledges – what shot Kurz ahead of the crowd was the move to install a modern ERP system in 2020. The effect on the service department has been radical in terms of transparency and communication with customers.

|

Nowak says utilizing Oracle Netsuite has enabled streamlining of internal systems and processes as well as providing outputs that clients are looking for.

“The service summaries we are able to generate are comprehensive and visible for our customers through a customer portal,” he explained. “I always think, as a consumer, I don’t want to take my asset to someone to be repaired, get a bill, and not know what I really paid for – so we want to show customers what the product looked like coming in, what specifically we did with the unit, and provide proactive information that can extend the life of the unit moving forward.”

Embracing technology has helped Kurz take service business away from competitors that don’t proactively communicate with customers whose electro-mechanical units are in for repair. Rather than forcing the customer to chase the service department for updates, Kurz technicians are able to keep customers apprised about service status and estimated time of completion.

LET’S CRAFT A SOLUTION

Overall, a major differentiator, Nowak says, is his company’s high technical knowledge coupled with a determination to solve customer problems – sometimes problems they may not know they have. Nowak coaches his team to ask questions and understand customer problems and what kinds of things they want off their desk. “Then, let’s figure out what is the solution that we can provide – is it in our toolbox? If not, we maybe need to add something to our toolbox. And if it is, let’s craft a solution,” he said.

“Although our workforce over time has gotten younger, we still have a number of technically knowledgeable people who we pair up with our salespeople to be able to provide that technical aptitude for application assistance that goes beyond just pulling a part number,” he continued. “This is something we really hang our hat on – we’ve got people here who have seen these applications, they know the products, and they can help provide that solution.”

|

One of the biggest challenges customers face today, Nowak observes, is having to do more with less. This is particularly true on the labor front – whereas a customer company may once have had a department of 20 experienced maintenance personnel in the past, today it might be a team of 12, many of whom may be recent hires without much experience.

“Our goal is to become the trusted advisors of those maintenance managers and bring technical knowledge and ways to support them in managing their department,” Nowak said. “Unfortunately, based on feedback I hear, great service has become more the exception than the norm in many industries including ours in recent years.”

SUCCESS IN SELLING

Having studied HR in college, Nowak has strong views about how to interact with people and applies key principles in both sales and leadership.

|

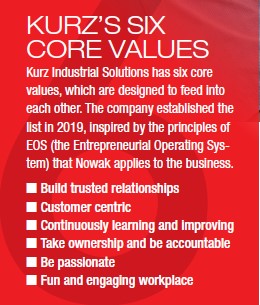

As an executive, he builds his own skill set through active participation in YPO, Vistage, and PTDA, as well as through reading and having regular contact with mentors. He’s learned that trying hard to not be a dictator can push you to the opposite extreme, so Nowak seeks a middle ground of being approachable while still holding everyone accountable. For his company, he harnesses the guidance of EOS, from which he and his team defined Kurz’s core values, and he places high value on daily, continuous improvement for all people and processes within the business.

On the sales side, it’s not uncommon for him to occasionally ride with salespeople to visit customers, and he uses the opportunity for coaching moments with tips he says will lead to success. They include:

(1) Be prepared – know in advance what you’re going to ask about and leave with the answers.

(2) Build multiple contacts at the customer organization, 8–10 if possible. If George can’t meet you at 9 because of a down machine, your trip won’t be wasted if you know you can stop in and see Fred, Joe or Al.

(3) Listen actively and take lots of notes, which demonstrates you are paying attention and shows the customer you value what they’re saying.

“The other thing is consistency,” he said. “For me, that applies to all aspects of life. I’m going to show up each day. Some days are going to be bad, some days are going to be good. Some sales calls are going to be fantastic, and some are going to be a bomb. But you keep showing up and you don’t fear rejection. Are you going to call it a day at 2 o’clock because you had a bad call, or will you bounce back and make the extra call before you go home?

“I got a piece of advice very early on from a supplier,” Nowak added. “He said in our industry, if you make 20 to 25 visits a week, you will succeed. Your learning curve will be quicker, and if you’re just consistent over time, there’s going to be a switch that flips. You’re going to have gained enough trust and enough relationships that they’re now looking for you, they’re demanding you, and you don’t even have to set up much of your week anymore.”

This article originally appeared in the September/October 2024 issue of Industrial Supply magazine. Copyright 2024, Direct Business Media.