|

Wear resistance starts with how the tool is made.

Staff Report

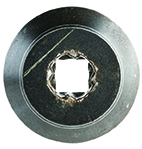

Traditional socket designs concentrate stress on the corners, increasing the likelihood of fractures under heavy loads. The Wright Square redistributes the stress away from the corners, offering enhanced durability and performance for users.

“At Wright, we are committed to innovation through our patented products, Wright Grip 2.0, Wright Drive 2.0, and Wright Square,” said Clark. “These tools have a focus on professional safety and reliability. We strive for ‘best-in-class’ for strength and durability, setting our tools apart with superior American-made quality.

“By focusing on innovative solutions and stringent quality control, we aim to deliver tools that outperform and outlast, reflecting our commitment to ‘perfecting performance’ in everything we do.”

Safety is a strong selling point for distributors, and it’s a major area of focus at Wright, according to Clark. The three innovations are engineered to reduce slippage and increase efficiency, helping to prevent accidents on the job and promote safety. Because tools are both effective and designed to minimize liability risks, distributor customers have increased profitability opportunities.

|

|

| A socket before (left) and after being abused by an electric impact gun. |

|

“During our forging process, we implement rigorous quality inspections to ensure our tools meet our high standards,” said Clark. “Our attention to detail guarantees that every tool not only upholds our demands but also lasts 3–5 times longer than other tools, exceeding industry norms.

“We are continually refining our processes to improve efficiency, resulting in better lead times and superior quality.”

Wright is committed to continuous innovation, says Clark, driving the company to improve upon its existing patents and explore new technological advancements in the quality department. The tool manufacturer integrates advanced technology to gain a deeper understanding of how its tools interact with other tools and attachments on the market – armed with that intelligence, the company refines and enhances its designs for a consistently better end-user experience.

“Our dedication to “perfecting performance” means that even though our patents have substantial longevity, we are always seeking ways to advance and improve,” said Clark. “We believe that there is nothing more personal than using a hand tool, and our tools reflect this by embodying more than just functionality—they represent a commitment to exceptional quality and consistency. Wright also focuses on experimenting and researching materials to better strengthen our tools and aim for better performance and durability. Through these ongoing efforts, we strive to ensure that our tools not only meet but exceed industry standards.”

STATE-OF-THE-ART MANUFACTURING

At Milwaukee Tool, innovation, dedication to users and investment in state-of-the-art manufacturing technology has resulted in multiple new top-performing hand tool solutions that are covered by a Milwaukee Lifetime Guarantee, according to Adam Moscherosch, director of product marketing. The company is delivering on these from its 95,000-square-foot research, design, and manufacturing facility in West Bend, Wisconsin.

“While there are many different solutions on the market, it all starts with how these tools are manufactured,” he said. “Manufacturing may not be the first thought on every professional’s mind, but it can directly affect the performance, durability, and lifetime of a tool. The manufacturing process can often mean the difference between a high-quality tool and one that doesn’t last.

“When tools are produced using outdated practices, they may appear to be more cost efficient in the moment but often lead to more spending in the future,” he added. “Low-quality tools can wear out quickly and frequently, which can negatively affect project budgets, deadlines, and user experience. Purchasing from manufacturers that prioritize innovative manufacturing processes, quality, and compliance often helps reduce the risk of tool failure and minimize spending.”

|

Key hand tool features to meet end-user requirements are performance, efficiency, and durability. Tools designed with efficiency in mind can reduce the number of tools required for a job, and more durable tools allow users to stay on the job rather than having to track down a replacement for a damaged or broken tool. Purchasing durable hand tools from a trusted manufacturer ensures professionals can stay efficient, productive, and safe on the job, says Moscherosch.

The company’s cutting pliers (USA made) have an ergonomic design that provides professionals with the easiest cuts while an optimized pivot point design gives maximum leverage to cut through tough materials. Frequent use of poorly-designed tools can lead to hand, wrist, and muscle strains – Moscherosch says investing in hand tool solutions with ergonomic designs can help prevent injury from repetitive actions over time. Helping to improve safety, these solutions are offered in comfort grip with a lanyard hole and dipped grip with a split-ring hole, which makes them tether-ready for complete tie-off while working at heights on the jobsite. The pliers are optimized for overhead and confined spaces, enhancing control and reducing fatigue.

BUILT FOR RELIABILITY

At The L.S. Starrett Company, reliability is a top priority for hand tools. One example is the company’s protractors, highlighted by Charlie Starrett, product manager, saws and hand tools:

|

Miter protractors are ideal for all building trades that require the measuring and transferring of angles, he says, taking error-prone calculations out of the process of miter cuts. A miter cut scale transfers readings directly to the miter saw for miter joints. Part of the popular Starrett ProSite 505 Protractor family, the 505P-7 7-inch Miter Protractor is ideal for carpenters, plumbers and all building trades that require the measuring and transferring of angles, miter cuts as well as being exceptionally helpful for DIYers. The series also includes the Starrett 12-inch Aluminum Combination Protractor, which provides 5-in-1 functionality with the ability to perform miter cuts, single cuts, act as a protractor or roof pitch, and offers a compound cut conversion table.

For industrial distributors that also serve the construction industry, Starrett’s jobsite hand tools include Pocket Scribers featuring a knurled and nickel plated steel handle. Their Adjustable Jaw Cut Nippers feature a special design including heat-treated steel frames for strength.

This article originally appeared in the September/October 2024 issue of Industrial Supply magazine. Copyright 2024, Direct Business Media.