Improving workplace air quality

By Rich Vurva

The coronavirus pandemic has focused attention on the importance that ventilation plays in warehouses and on plant floors. Manufacturers of industrial fans are helping to spread the word about how a well-designed system can help prevent the spread of germs.

“In most warehouses, there’s a lack of HVAC or air conditioning systems. With proper exhaust and ventilation, building owners and operators can maximize the amount of clean, fresh air that is in a space. Circulation provided by large overhead fans is crucial in that process,” explains Alex Risen of Big Ass Fans.

|

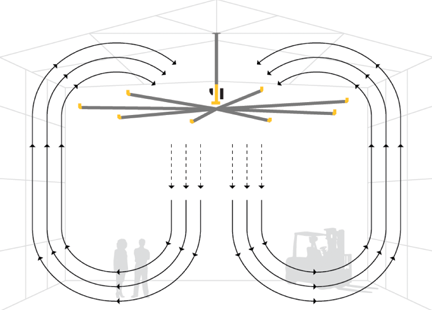

| HVLS fans prevent stagnant air and are the best solution to improve air mixing. |

Risen explains that fresh air is not typically distributed uniformly throughout a space. For example, one of the most common air distribution configurations for HVAC systems is an overhead supply with overhead return. In common heating applications, this ceiling configuration can cause significant stratification of heated supply air and room air layers that prevents fresh air from circulating to occupant level. To compensate, the ANSI/ASHRAE Standard 62.1 requires ventilation rates be increased by 20 percent to deliver the necessary amount of fresh air to the room’s occupants.

“In naturally ventilated spaces, fresh air is passively distributed throughout the space, so localized areas may have stagnant pockets that result in poor air quality and the buildup of pollutants. Big Ass Fans disperse these pockets and increase the circulation of fresh air, evenly distributing it throughout the space and improving indoor air quality,” Risen says.

According to a study published in Environmental Health Perspectives, the use of upper-room ultraviolet germicidal irradiation (UVGI) can help improve indoor environments. To maximize elimination of pathogens, upper-room UVGI systems rely on air movement between the lower portion of the room, where droplet nuclei (from a sneeze or cough, for example) are generated, and the upper, irradiated portion of the room. When upper-room UVGI systems are installed, ventilation systems should be designed to provide optimal airflow patterns for heating and cooling and prevent air stagnation or short circuiting of air from the supply diffusers to the return or exhaust grills.

|

| Study data reflect that in a room without adequate air mixing, UVGI system effectiveness increased from 12% to 89% when an overhead fan was used. |

Risen says that every ventilation application is unique because systems in different climate zones are unique. Ventilation and circulation can be calculated by HVAC engineers to design the proper system and utilize fans to maximize that system’s efficiency, whether during new construction design phase or a retrofit of an older building.

“Upper Room UVGI systems combining our HVLS fans, and our smaller Haiku model, would help clean the air in the occupied space in both conditioned and non-conditioned spaces. We’re on the cutting edge of delivering ions to spaces with our patented products as well. There are huge benefits in making the air safer while still delivering the comfort necessary with safe, efficient products,” Risen says.

Keith Simon, senior development manager at Airmaster, says protection against viral transmissions is composed of several components, with personal protective equipment (PPE) being the first line of defense. However, there are ways to improve air quality in large, non-air conditioned spaces.

“No one knows how much virus it takes to transmit the illness, and trying to estimate the amount of viral particles expelled by an unknown number of infected people makes this a nearly unsolvable problem,” he says. “There is general agreement, however, that the lower the viral contamination, the less chance of transmission of infection.”

The more outside air you bring into an environment lowers the viral concentration and therefore lowers the risk. Perhaps the best method of providing dilution air to a factory or warehouse is the use of panel fans or roof ventilators. Both are mounted well above the floor, and produce a constant low velocity airflow while providing large amounts of dilution air.

“The traditional methods of ventilating an industrial building remain among the best way of providing dilution of air,” says Simon. “This is because the velocity from these devices dissipates before the air reaches the work floor.”

|

| Airmaster heavy-duty mobile filtered fan-belt drive removes dust particles and airborne contaminates from circulated air. Available with MERV filter. |

In the past, facilities might have used a single large air circulator that sent air down the length of an assembly line cooling a large number of workers. This approach is not advisable today because it risks carrying contamination from worker to worker. Instead,

Airmaster suggests using multiple smaller air circulators perpendicular to the assembly line, creating a “dirty zone” behind the line of workers. It’s best to tilt the air circulator in a downward direction so that any contamination goes toward the floor.

Airmaster advises against using oscillating fans during the pandemic because the constant movement makes it difficult to control the direction of airflow.

Airmaster recently introduced a 30-inch heavy duty mobile filter fan with a MERV filter that removes dust particles and airborne contaminants from circulated air. An air filter’s minimum efficiency reporting value (MERV) rating measures how effectively the filter stops dust and other contaminants from passing through the filter and into the air stream. Filters with higher MERV ratings trap small particles more effectively than filters with lower MERV ratings.

Air quality a major worker concern

Last year, a Harvard Business Review survey reported that the number one workplace wellness perk that employees most desired was air quality. Air quality received 58 percent of the survey vote, with the option for an on-site gym receiving only 16 percent. “Keep in mind, this was before the COVID-19 pandemic, so I imagine this stat has drastically increased in favor of air quality in the workplace,” says Mark D’Agostino, senior vice president and general manager of Hunter Industrial Fans.

D’Agostino says high volume, low speed (HVLS) ceiling fans are a tremendous asset in improving a facility’s air quality. By improving temperature control in buildings, you’re creating a more comfortable, healthier work environment.

HVLS fans can be as small as seven feet and as large as 24 feet with various sizes in between. These industrial ceiling fans provide large-scale airflow that regulates temperature while preventing stagnant air and a dust-riddled environment. High air turns also help eliminate toxic airborne chemicals.

Additionally, HVLS fans can manage a facility’s moisture, which can form on the walls and equipment in the plant or factory floor in between two different climate-controlled environments. Proper indoor air movement can quickly dry this condensation to reduce fall risks, pollutants and bacteria associated with unchecked moisture.

“We have seen companies experience reduced absenteeism and employee complaints, coupled with boosts in overall productivity,” D’Agostino says.

An industrial ceiling fan also minimizes the energy consumption per square foot of the facility in which it is installed, equaling a cost savings of about $1 per day to operate.

During the winter months, buildings with high ceilings often experience significant heat stratification, where warmer air rises to the ceiling and cooler air remains at floor level. Heat stratification forces a facility’s heaters to work two to three times harder to keep employees and building occupants adequately warm while most of the heat continues to be trapped above their heads.

By evenly distributing warm air and allowing HVAC systems to work more efficiently, HVLS fans can save up to 30 percent on heating costs.

“One Hunter Industrial customer reported that his heating bills reduced by an average of $2,500 annually compared to before the fan was installed. HVLS fans not only save money long-term, but pay for themselves in no time,” D’Agostino says.

A building’s indoor air quality and temperature are critical factors that influence everything, from the heating bill to employees’ health. HVLS fans provide comprehensive solutions to improve indoor air conditions and ultimately optimize a facility’s efficiency, comfort and savings.

This article originally appeared in the Sept./Oct. 2020 issue of Industrial Supply magazine. Copyright 2020, Direct Business Media.