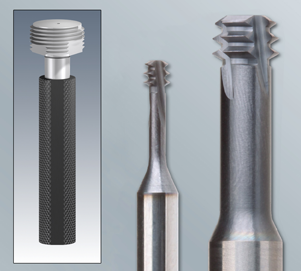

Emuge-Franken Self-Lock threading tools

Emuge-Franken has expanded its line of Self-Lock thread locking tools to include new Emuge ZGF-S-Cut Thread Mills, in addition to Emuge High Ramp Precision Thread Gages designed for gaging Emuge Self-Lock thread profiles.

The new ZGF-S-Cut Self-Lock Thread Mills with helical flutes, multiple teeth and TIALN-T46 coating produce self-locking threads that are ideal in demanding industry applications such as aerospace where nickel alloys, titanium and stainless steel are the norm. A unique design enables three tooth pitches to simultaneously rough and finish-cut threads, dramatically increasing tool life and reducing cycle times.

The new ZGF-S-Cut Self-Lock Thread Mills with helical flutes, multiple teeth and TIALN-T46 coating produce self-locking threads that are ideal in demanding industry applications such as aerospace where nickel alloys, titanium and stainless steel are the norm. A unique design enables three tooth pitches to simultaneously rough and finish-cut threads, dramatically increasing tool life and reducing cycle times.

“As the demand for self-locking threads for safety critical applications increases, our new ZGF-S-Cut Self-Lock thread milling products with unique geometry provide more threading options,” said Marlon Blandon, Thread Milling Product Manager, EMUGE-FRANKEN USA. "Interest in our Self-Lock threading tools, which have been successfully applied for years, continues to rise.”

The new Emuge ZGF-S-Cut self-locking thread mills have a left-hand helix flute design with left-hand spindle rotation, which greatly enhances stability and cutting performance. The first of three cutting teeth acts as a rougher, while the second and third teeth finish the full thread profile, providing perfect threads, exceptional cycle time reductions and longer tool life. TIALN-T46 coating resists heat and wear and further extends tool life. “Our ZGF-S-Cut design provides tool life which can exceed 10 times that of conventional thread mills,” said Blandon. The new thread mills are available in 16 sizes from 2-56 up to ½-20" for UNC or UNF threads, and tools starting at the ¼" size and larger feature axial coolant capability.