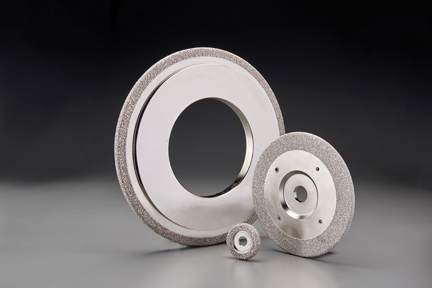

Norton Winter Ironclad Foundry Grinding Wheels

Saint-Gobain Abrasives announced the introduction of its new patent-pending Norton Winter Ironclad Diamond Single Layer Superabrasive Wheels that achieve maximum material removal for increased productivity, especially when used in automated grinding cells.

Featuring the strongest and most durable bond on the market, Ironclad wheels finish up to 50 percent more parts per wheel compared with electroplated wheels. Norton Winter Ironclad Wheels are a superior solution for ductile and grey cast iron applications such as fettling and snag grinding on casting gates, parting lines, sprues, and more.

Featuring the strongest and most durable bond on the market, Ironclad wheels finish up to 50 percent more parts per wheel compared with electroplated wheels. Norton Winter Ironclad Wheels are a superior solution for ductile and grey cast iron applications such as fettling and snag grinding on casting gates, parting lines, sprues, and more.

"The advanced, high performance bond has up to 75 percent grain exposure, offering heat resistance and lubricity to achieve larger depths-of-cut and cooler cutting," said Andy Schoch, product manager for Single Layer Products, Norton│Saint-Gobain Abrasives. "The unique bond also reduces friction, allowing for lower grinding power. Norton Winter Ironclad Wheels provide significantly higher stock removal rates and a lower cost per part compared to other standard plated products." The new wheels produce more burr-free parts, minimizing secondary operations.

Norton Winter Ironclad Wheels offer several additional benefits including reduced downtime due to longer wheel life which extends time between setups. There is less bluing of castings even towards the end of the wheel life. Promoting a cleaner, healthier work environment, the new wheels generate significantly less dust and odor compared with traditional bonded wheels.

No wheel dressing is required and the rigid steel hub reduces vibration during CNC grinding. A known grinding wheel location facilitates easier programming, and a rigid steel hub reduces vibration resulting in consistent wheel dimensions and minimal wheel wear.