Sandvik Coromant micro drills

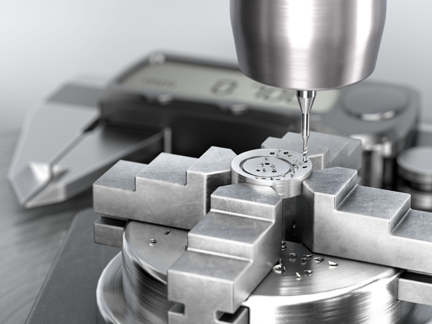

Sandvik Coromant has launched two new microdrill families specifically designed for precision machining.

The CoroDrill 462 with -XM geometry and the CoroDrill 862 with -GM geometry support industries with high demand for small part manufacturing, including medical, automotive, electronics and aerospace. Designed to cover a variety of workpiece materials, the new drills offer precise performance where accuracy is key.

The CoroDrill 462 with -XM geometry and the CoroDrill 862 with -GM geometry support industries with high demand for small part manufacturing, including medical, automotive, electronics and aerospace. Designed to cover a variety of workpiece materials, the new drills offer precise performance where accuracy is key.

Devices across several industries are shrinking in size. This can be seen most clearly in electronics, with modern devices offering ever greater capability in smaller packages. Elsewhere, in medical device manufacturing, the rising trend of minimally invasive surgery — using techniques that minimize the size of the incisions a surgeon makes — requires increasingly intricate tools. As the size of technology scales down and its level of sophistication scales up, manufacturers demand tools that can produce smaller, more complicated parts.

Drilling specialists generally use the term micro drilling when describing holes smaller than three millimeters (mm) in diameter. This can refer to holes often encountered in the electronics industry, where workpieces are just a few hundredths of a millimeter thick, but more common applications include the aerospace industry, mold and die making and medical equipment manufacturing.

The CoroDrill 462 and 862 are the next generation of micro drills from Sandvik Coromant. Available in new geometries to offer a wide variety of cutting diameters and lengths, the drills boast an increased product range compared to previous assortments.