Midwest Precision Product adds hand feed grommet press capabilities

Midwest Precision Products recently included Hand Feed Grommet Press capabilities to its suite of product services.

|

|

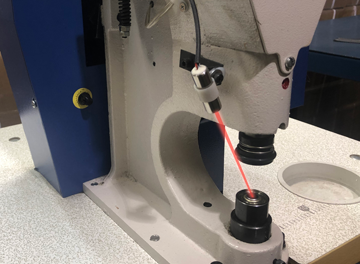

Designed for efficient production runs for small-to-mid-range projects, the addition of this economical and versatile hand feed setting machine operation allows MPP to set plain sheet metal grommets, and self-piercing grommets and washers. The press leverages a built-in laser light pointer to easily and accurately locate the center of the setting target area for a perfect grommet hole and secure setting. Notably, MPP’s grommet setting operation features on-site tooling for key basic types of industry standard grommets including:

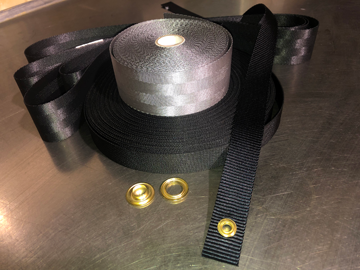

WEBBING PROJECTS: #0: Plain Sheet Metal Grommet & Flat Washers

The #0 (1/4” hole size after setting) grommet is typically used for our seatbelt webbing–these are the most commonly used grommets. Because the webbing is tough, it is a two-step process: A hole is punched through the webbing with one set of tooling, then the grommet is secured through the punched hole with a second set of tooling.

▪ Stocked 2” wide black polyester MPP seatbelt style webbing

▪ Stocked in Brass; Nickel & Black Ox available

▪ The flange of the grommet is slightly domed & the edges are flat

▪ The accompanying washer has a slight cup in it

▪ Grommet flange diameter (.545) / Length under flange (.175)

▪ Inside diameter of washer (.289) / Outside diameter of washer (.546)

BANNER AND TARP PROJECTS: #3: Self-Piercing Grommets And Washers

The #3 (7/16” hole size after setting) self-piercing grommet is used for thin material–like a plastic tarp used for banners and vinyl. This is a one step process where the grommet itself pierces the hole, and secures itself in one hit on the machine:

▪ Using customer supplied material – assemblies

▪ Stocked in Brass; Nickel & Black Ox available

▪ Self-Piercing grommets can pierce your material without pre-punching a hole

▪ Heavier gauge metal than plain grommets

▪ Grommet flange diameter (.970) / Length under flange (.185)

▪ Inside diameter of washer (.546) / Outside diameter of washer (.970)

“Adding this versatile grommet operation will allow customers to leverage another turn-key production capability under one roof. This will compliment the benefits of our sustainably “green” seatbelts and pallets system when there is an on-demand need,” said Jeff Rogers, MPPs president.