Reel Needs

By Kim Phelan

When distributors think about the industrial applications for which customers rely on hose reels, two descriptions probably come to mind: rugged in the extreme and almost immeasurably diverse. And the myriad punishing environments in which they’re used is only surpassed in complexity by the “what” that’s being applied – substances ranging from water, air and fuel to lubricants, pneumatic fluids, power, and more. The high and evolving demand for hose reels is keeping manufacturers in high-response mode.

|

| Jennifer Wing |

Little wonder that durability, reliability and ease of service are the leading drivers of product development in the hose and cable reel market, according to Jennifer Wing, marketing manager at Hannay Reels.

“Reels need to work on a daily basis and multiple times a day in every market they serve,” she said. “Improvements to bearings and motors, different spool or frame options and even upgrades to a reel’s finish ensure the reel will work every time, and last longer in harsh environments.”

Hannay Reels has responded to customer demands in its engineering department where upgrades and improvements to reel components have become a top priority.

Recent upgrades, said Wing, include offering the reel industry’s first IP68 certified motor – the IP68 standard is defined as having complete protection from ingress of dust, and, more importantly, a very high level of sustained protection from water ingress. These new motors feature two large O-ring seals and shaft seal that help protect the motor armature and brushes from water and particle ingress, providing longer life to each motor.

Recent upgrades, said Wing, include offering the reel industry’s first IP68 certified motor – the IP68 standard is defined as having complete protection from ingress of dust, and, more importantly, a very high level of sustained protection from water ingress. These new motors feature two large O-ring seals and shaft seal that help protect the motor armature and brushes from water and particle ingress, providing longer life to each motor.

Starting in 2023, a gear box will be available that is in-line and mounted directly to the motor and will offer a manual declutching mechanism for easy unwinding of the reel. This gear box will be offered in three different gear ratios suited for diverse applications. The assembly is sealed, can be easily added to reels in the field, and does not require any field maintenance.

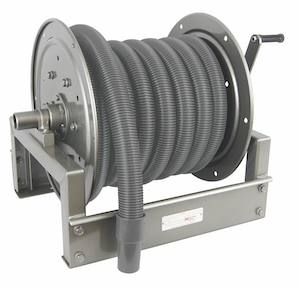

In addition, due to requests from customers, Hannay Reels now offers Industrial Vacuum Reels for the collection of dust and debris. These reels are designed for auto detailing, machine shops and any facility that uses industrial vacuums with 1 1/2-inch and 2-inch I.D. hose for cleanup. Reel models are available in manual or spring rewind with different frame and mounting options.

The company says commitment to advancement is imperative to improving quality in its product lineup.

“Advances in technology, materials, and products are important to providing a reliable product year after year,” Wing said. “A recent investment in a precise laser measuring tool has allowed our engineering and quality department to optimize quality control operations by inspecting complex parts and pinpoint defects with superior accuracy.

“Hannay Reels is always looking to the future and new technologies,” she added. “We look forward to continued customer feedback and improving our products.”

The Call for Customization

While the size and scope of hose reel inventories are far reaching indeed, demand for something new and unique has been a catalyst for the service of customization. When distributors can’t locate the perfect reel for a specific application, Coxreels says it has the capability to custom build any product to exact specifications.

While the size and scope of hose reel inventories are far reaching indeed, demand for something new and unique has been a catalyst for the service of customization. When distributors can’t locate the perfect reel for a specific application, Coxreels says it has the capability to custom build any product to exact specifications.

Coxreels custom-built products offer a complete solution to any hose, cord, and cable reel needs. Offering custom design expertise and manufacturing flexibility, the company manufactures a complete and diverse line of custom reels, as well as thousands of standard products.

With 93 years in the hose, cord, and cable reeling industry, Coxreels analyzes individual customer requirements and provides the best reeling solution for the application at hand.