Grainger's Hat Trick

|

| Paige Robbins, senior vice president at Grainger and president of the company's business units. |

How they keep scoring their no. 1 goal

by Kim Phelan

It’s easy to picture industrial distribution as a hockey match when you talk with Paige Robbins, senior vice president at Grainger and president of the company’s business units. A lot of her non-working hours are consumed in the stands with other “hockey moms,” she says, rooting for her sons who play at high-school and middle-school levels. But when the dialog turns to business, you get the sense that this analytical executive is in it to win it in the distribution game, applying strategies designed to pound on one goal again and again: improving customer experience.

It’s not a glib phrase in the Grainger arena, and Robbins doesn’t take her eyes off the goal or the scoreboard. Within the sphere of her influence and responsibility, she’s a relentless customer advocate driven by three top priorities: (1) investing in technology and automation to give the customer more money-saving services, (2) expanding product assortment to satisfy more procurement demands, and (3) equipping sellers and field teams who serve and solve on the front lines.

|

Robbins’ playbook is drawn from continuous, in-person visits to customer work facilities as well as customer C suites, because it’s the only way to understand the unvarnished truth about their evolving needs, problems, and pressures.

Informed by those frequent pulsechecks, she noted that customer sentiment at the close of 2025 was mixed depending on the industry, but overall, she said customers were cautiously optimistic that stability will characterize 2026.

“Cost is also always on their mind,” Robbins said, “and even more so these days. So, we’re having conversations about total cost of ownership and how can we really reduce costs for them. And they’re open to that.”

She adds that labor is an everpresent stressor for customers, as well, and they’re seeking solutions from Grainger to provide even greater levels of onsite services.

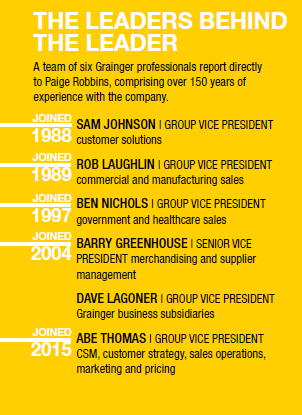

A skilled team builder and a mathematically minded strategist, Robbins says she leans into a deep bench of six highly experienced and talented direct reports who form her senior management team – and 9,000 employees work under those leaders, a third of whom comprise the field sales force, and the company is currently hiring more. “We have found if sellers spend more time with customers, that is good for customers and good for Grainger,” she said. “So we’ve been going through a multi-year process of hiring more sellers so they can invest that time to understand customer priorities and help them reach their goals.”

|

Through a cadence of regular team and individual meetings, she develops and communicates her customer-driven plans but takes a hands-off approach for execution. Proud of her team and protective of their wellbeing, Robbins is both a road warrior and a calendar warrior who proactively guards family time but also blocks generous allowances throughout the year for strategic reflection alone and with her team.

BETTER REPORTING FOR CUSTOMERS

|

For 2026, one of Robbins’ key objectives will focus on further investment in Grainger’s KeepStock inventory management system, known in the industry as vendor managed inventory.

“One of the areas we are building is in the reporting we do for our customers. We’re going to provide even better analytics – not just reporting for reporting’s sake. It’s reporting to help customers take out cost.

“And through our inventory management, we can look across their sites and see consumption patterns and other trends. We are investing in technology to make it easier for the customer to access this data. I’m very interested in creating ways to bring more customer insights that will help them take cost out and remove the challenges they have.”

Robbins is also interested in removing more burdens and distractions so customers can stay focused on their core competencies. “MRO is messy,” she added. “No one really wants to manage MRO. We can help them manage it, and we can help them save money – and time – if it’s something they’re trying to find that they don’t buy every day.”

|

| Nine thousand employees work under the direction of Robbins and her senior management team comprised of six highly experienced distribution experts. |

With abundant presence in customer locations, Grainger is preparing to further support the spread of automation in factories. Robbins hinted the distributor is moving toward increasing products and maintenance services in this area.

Expanding inventory is another key offensive maneuver in Grainger’s 2026 tactical plan. The company hosts a biennial Grainger Show bringing suppliers and customers together, and their upcoming March event in Orlando will feature new and innovative products the distributor and its supplier partners are rolling out. Presently, Grainger offers over 2 million products in its High-Touch Solutions business and serves 4.5 million active customers.

|

“We’re always looking at improving our assortment, so there are new products that we will add – new categories,” she said.

AI AND SELLING

No stranger to AI – even well before the onslaught of Chat GPT – Grainger is widening its lane in e-commerce search. Robbins says there’s much more the company will do with search, particularly with large language models, making sure customers experience increased simplicity and speed in finding the product they’re after. Related to customer experience, the distributor is also pursuing more ways to harness AI within its customer service centers to provide rapid answers to every customer inquiry.

But Robbins is also exploring how AI can support the company’s sales team.

“For that visit to the customer, how can we make the seller more knowledgeable?” she said. “We don’t have the answer yet, but we’re experimenting. How can we help our sellers help our customers and sell more? Are there tools we can build to support them even more? We’ve done some things, and we’re looking at what more we can do.”

Sellers are never far from her thoughts. As she reflects on the year ahead, there isn’t much that troubles Robbins, but the care of Grainger’s people is an ever-present focus.

“What I get concerned about is my teams – are they getting burned out?” she said. “How do we make sure that we’re giving them enough time to restore, and do we know what’s going on? It can be hard, especially in the field, and so one of my concerns is, how do we make sure we are investing in our teams. A lot of them are out in the field, and while they’re not completely on their own, it can feel more isolated.”

|

But optimism for the future far outweighs worry on Robbins’ business sentiment scale.

“I am really excited about Grainger,” she said. “I look at the investments in technology that we make. We’re also making investments in supply chain. We’re improving our customer experience and building new buildings, and I’m just excited I work for a company that continues to invest and focus on the customer. And we’re just scratching the surface in terms of what we’re doing with product information, customer information, and how we can help customers.

“Many of our customers are unsung heroes, keeping their facilities up and running,” she continued. “I get a lot of satisfaction when we can help them do their jobs better. And there’s a lot more coming that we can do.”

FINDING FINGERPRINTS

Robbins joined Grainger in 2010, leaving her partner/managing director role at a consulting practice to come and head up the distributor’s supply chain division. Fifteen years and numerous promotions later, her fingerprints are all over the company. In some places, the effect is that of a potter who has molded and shaped major systems – work that impacted the direction and growth of the No. 1 industrial distributor in the U.S., according to MDM’s annual research.

|

When she started, Grainger was a branch-based distribution leader that had scaled and evolved from its 1920s origins of selling motors. But times were changing, and customers were moving away from always wanting to come into the stores.

“E-commerce was coming, and we had to transform from being a supply chain that was based on replenishment to branches to one that was able to direct ship to customers, next day ship complete,” she said. “That means you have to have all the inventory in one building. You have to be able to take an order by 5 p.m. and ship it out. And our average order size is about $500, so we’re talking about lots of little orders.

“The team and I had to think about investing in these bigger distribution buildings, as well as the transportation network and the staffing to shift from a branch supply chain to a direct-to-business supply chain,” she continued. “It required some really hard choices about branches, and we had to close many of them.

“But I am really proud of how we evolved the supply chain, because if we hadn’t, we wouldn’t be getting the customer what they wanted. My motto became, ‘Shift to Ship.’ It took a while for everyone to understand what I was saying, but the new reality was, the customer is not going to pick it up anymore.”

Today, Grainger says it can reach 99% of U.S. postal codes next day and 80% of Canadian postal codes. But far from abandoning branches, Grainger offers 364 walk-in locations in the U.S., Canada, Mexico, and Puerto Rico.

|

|

Another transformation she effected began with an unexpected twist. In 2019, CEO D.G. Macpherson asked Robbins to take over Grainger’s technology team. She became senior vice president and chief technology, merchandising, marketing, and strategy officer.

“He said we needed to transform this company into a technology organization that’s aligned to the business priorities that create value for our customers,” Robbins said. “So, I was responsible for leading that transformation, and I’m proud of the people we hired, including Jonny LeRoy, our chief technology officer. Then we really did some restructuring and aligned the Grainger Technology Group (GTG) around product information and customer information – because when you know your products better than anyone else and your customers better than anyone else, good things happen.

“I couldn’t do my current role if I hadn’t done that job well,” she added. “I’m really thankful to lots of people in the technology organization who taught me so much at that time.”

A WORD OF ADVICE

Sitting in a conference room at Grainger’s 1.8-million-square-foot distribution center in Minooka, Illinois – about 50 miles southwest of downtown Chicago and 70 miles southwest of its global headquarters in Lake Forest – Robbins reflected on what she would say if she was speaking to another distributor instead of a journalist.

|

“The best advice I could give is to continue to focus on the customer and make sure you’re understanding your customers’ needs, how they’re evolving, and their pain points,” she said. “If we hadn’t understood how our customers were changing and then innovated the way we did over the past 100 years, we probably would not be in business. The world is dynamic, it’s always changing. You can’t just read about those changes – you need to go see the customer and understand what’s going on with them.

“The second thing I would say is, if you’re not very familiar with technology or AI, make sure you understand it – but that doesn’t mean putting it toward every problem. But understand it as you’re solving customers’ problems – it’s going to matter; it’s going to be really important.”

|

This article originally appeared in the January/February 2026 issue of Industrial Supply magazine. Copyright 2026, Direct Business Media.