|

Staff Report

His colleague, National Sales Manager Mike Patterson, added, “We’re seeing it every week in the field. Ideally, cutting tools can handle 80% of the work – across a wide range of materials – without needing to swap out tools or slow down setups. That’s why the demand for high-quality, multi-material cutting tools is growing fast. Shops want simplicity without sacrifice.”

To meet that high bar, the company designed the MultiTOOL line – MultiTAP, MultiDRILL, and MultiTHREAD MILL – which are engineered to handle up to 80% of everyday jobs, cutting across carbon steels, stainless, aluminum, and more. “That makes them ideal for job shops, general machining, and high-mix/low-volume environments,” Bowles said.

According to Patterson, the benefits to distributors are tangible.

“It means faster quoting, reduced inventory complexity, and fewer call-backs,” he said. “The Multi- TOOL line helps even less experienced reps recommend the right tool with confidence. It’s an easy entry point to EMUGE-FRANKEN quality – but with the flexibility shops need today.”

MultiTOOL products feature advanced cutting geometries and next-gen coatings to extend tool life, improve chip evacuation, and reduce operator error – particularly helpful with a less experienced workforce or automated machining setups. “We’ve built these tools for broad performance, but not at the cost of quality,” said Bowles.

|

| EMUGE-FRANKEN USA's MultiTOOL line meets the demand for high quality multi-material cutting tools making them ideal for a variety of applications. |

“And when a shop runs into a job where a multi-material tool isn’t enough – whether it’s Inconel, hardened steel, or a mission-critical aerospace thread – we’ve got them covered,” Patterson said. “EMUGE-FRANKEN offers one of the most comprehensive lines of material-specific threading tools in the world, and a growing line of both universal and material-specific end mills engineered for the most demanding applications.

“That’s what makes our distributor partners so successful,” Patterson continued. “They can start with a versatile, value-driven MultiTOOL, and when the requirements get tougher, they can lean on our application support team and our high-performance tools to close the gap.”

Bowles added, “Distributors don’t just need another tool line. They need a partner who helps them win more jobs, serve customers better, and grow margins. That’s what we’re building with MultiTOOL and beyond.”

Patterson stated that while MultiTOOL is a great “workhorse” solution, EMUGE-FRANKEN isn’t a one-size-fits-all company. “We back up that 80% solution with some of the most advanced cutting tool technologies on the market.”

INNOVATION TO MEET EVOLVING CUSTOMER DEMANDS

At Champion Cutting Tool Corp., President and CEO Lowell Frey says the cutting tool market is driven by the need for faster performance, longer tool life, improved safety, and greater cost efficiency.

“End users want solutions that save time, reduce operator fatigue, and deliver consistent results even in the most demanding applications,” Frey said. “These trends reflect the realities of skilled labor shortages, tighter schedules, and rising material costs.”

The company says it’s addressing these challenges with innovations that help distributors serve customers more effectively.

For example, the Brute product line – including twist drills, taps, and reamers – is engineered for maximum strength, precision, and longevity. The tools help customers complete jobs faster with fewer replacements.

“Our RotoBrute SB35 semi-automatic magnetic drill press automates structural steel hole-making, freeing up operators and significantly boosting productivity,” Frey said. “Champion’s XLT electric tapper makes tapping easier and faster, producing precise threads while reducing manual effort.

|

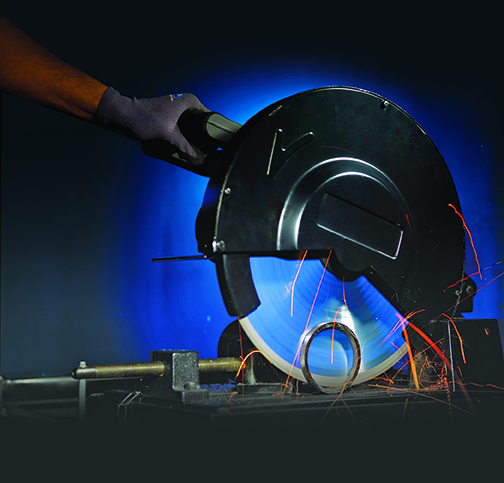

| Champion Cutting Tool's cement RZR saw blades produce smooth cuts with less noise and vibration, enhancing operator comfort and safety while offering exceptional blade life. |

“For abrasives, our ceramic flap discs remove material faster, last longer, and run cooler to cut downtime and deliver cleaner finishes,” he added. “In sawing, our cermet RZR saw blades produce smoother cuts with less noise and vibration, enhancing operator comfort and safety while offering exceptional blade life.”

To further extend tool life and improve workpiece finishes, Brute- Lube cutting compounds reduce heat and friction during cutting.

Champion also continues to innovate with high-molybdenum steels, nitride-treated surfaces, advanced geometries, and cermet-tipped saw blades. “These all contribute to helping distributors provide their customers with durable, high-performance solutions for tough jobs,” Frey said.

“By staying ahead of industry trends and listening to customer feedback, Champion Cutting Tool provides distributors with a competitive edge – offering high-performance solutions that are easy to sell and help customers stay productive, safe, and satisfied.”

This article originally appeared in the November/December 2025 issue of Industrial Supply magazine. Copyright 2025, Direct Business Media.