Biobased alternative to traditional rust preventative oils

Do sustainability and good business decisions contradict? Not necessarily. Companies like Cortec are making it possible to get necessary product functions while primarily using renewable raw materials. When it comes to metal rust preventative oils, EcoLine 3690 is among the best, competing with some of its own non-renewable counterparts.

EcoLine 3690 is a canola-oil-based rust preventative for long-term protection of metal components. It leaves behind a thin oily film that clings to metal surfaces and protects in severe conditions such as high humidity and marine environments.* EcoLine 3690 contains 72% USDA certified biobased content, replacing a large portion of the non-renewable content present in traditional oil-based rust preventatives.

EcoLine 3690 is a canola-oil-based rust preventative for long-term protection of metal components. It leaves behind a thin oily film that clings to metal surfaces and protects in severe conditions such as high humidity and marine environments.* EcoLine 3690 contains 72% USDA certified biobased content, replacing a large portion of the non-renewable content present in traditional oil-based rust preventatives.

Worker Benefits

As a wet-film corrosion inhibitor, EcoLine 3690 is especially ideal for users who like the properties and performance of VpCI-369 but are looking to try a “greener” option that is even friendlier to workers and the environment. EcoLine® 3690 is considered zero VOC and has no hazard statements. It can be applied via spray, dip, or brush. When the protection period is done, EcoLine 3690 is very easy to remove with an alkaline cleaner such as those in the VpCI-41x series.

Where to Use EcoLine 3690

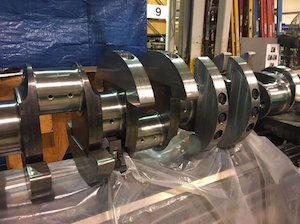

EcoLine 3690 can be used in practically any application where VpCI-369 is typically used. This includes automotive service parts, piping, tanks for air brake systems, moving parts on large equipment, and much more. While EcoLine 3690 is primarily used for rust prevention during extended storage, it can also be used to provide protection in-process, in-transit, or as part of a full-scale site mothballing plan.

User Feedback 1: Long-Term Storage of Auto Service Parts

EcoLine 3690 has been out on the market for more than a decade and has been gaining increasing acceptance in the last several years. In 2019, it was used by a company that needed to prep automotive service parts for up to 10 years of storage. Two camshafts and one cylinder head were coated by hand with EcoLine 3690 and subjected to corrosion testing. The product met requirements and was subsequently written into the automaker’s aftermarket engineering specifications. The company applying EcoLine 3690 was very happy with the product and its environmental and worker benefits in contrast to the previous rust preventative, which had been used for decades and was not only difficult to remove but also raised environmental and safety concerns.

User Feedback 2: Protecting Pipe Ends

In another case, a manufacturer of tubes for fire protection systems selected EcoLine 3690 for use on the ends of 30 foot (9 m) pipes. These ends were missed during the fast-paced painting process and required supplementary protection during 9-12 months of outdoor storage. The manufacturer did a trial of EcoLine 3690 on a small test bundle stored outside for about eight months, was impressed with the results, and subsequently adopted it for use. “The product works well and is safe for our employees,” the client commented. “That’s all we need and we are glad to be using it.”

With EcoLine 3690, renewability and worker-friendliness do not mean poor performance. Instead, positive feedback is the norm. While EcoLine 3690 is not ideal for every application, many users will find it a good alternative to traditional oily rust preventatives. The best way to find out if EcoLine® is right for your rust preventative job?